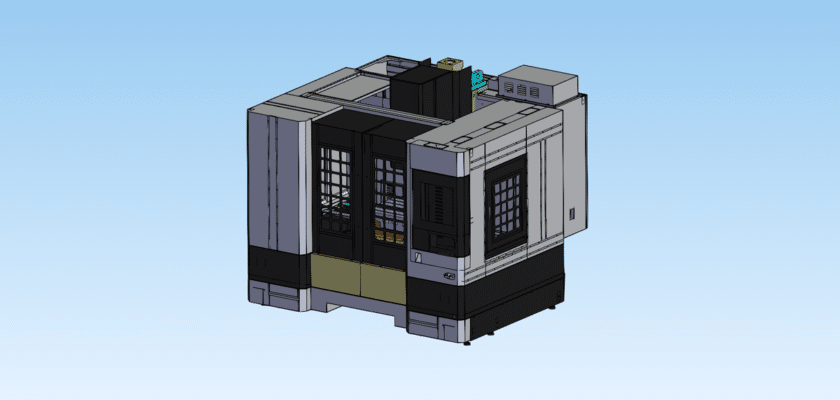

Le Taizheng 850 Machining Center is widely recognized in the manufacturing industry as a versatile and reliable vertical milling solution. This comprehensive engineering drawing provides a detailed look at the structural and mechanical layout of the 850-series VMC, a machine favored for its balance of worktable travel and compact footprint. For facilities looking to perform routine maintenance, design custom workholding, or integrate automated loading systems, having an accurate blueprint of the machine’s internal architecture is indispensable.

This technical document covers the essential X, Y, and Z-axis travel limits, spindle assembly details, and tool changer configurations. By downloading this drawing, you gain insight into the machine’s foundation, including the high-rigidity cast iron bed and precision linear guideways. The layout provides the exact dimensions for the T-slot table, allowing your team to design fixtures that maximize the machining envelope without risk of collision. Whether you are troubleshooting a mechanical assembly or planning a shop floor layout, this resource offers the verified data necessary to ensure your Taizheng 850 operates at peak performance.

Utilize this industry-standard reference to understand the lubrication paths and sensor mounting points critical for the machine’s longevity. At MechStream, we provide the blueprints that help you maintain and optimize your high-value capital equipment. Download this high-fidelity technical asset today to keep your production line moving.

Caractéristiques principales :

- Optimized 850mm X-Axis Travel: Provides a clear map of the working envelope, ensuring safe and efficient tool path programming for medium-sized parts.

- Rigid Spindle Housing: Detailed design of the spindle head assembly, optimized for both high-speed finishing and stable heavy-duty milling.

- Automatic Tool Changer (ATC) Interface: Includes mounting and clearance specifications for the umbrella or arm-type tool changer systems.

- Integrated Coolant and Chip Trays: Features a layout designed for efficient thermal management and rapid waste removal during high-volume production.

- High-Precision Linear Guides: Detailed specifications for the bearing blocks and rails that ensure repeatable positioning accuracy across the entire travel range.