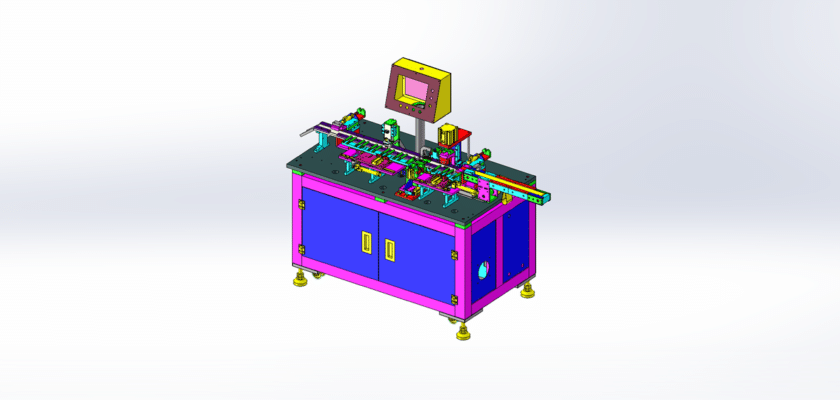

Le Terminal Connector Press-In Inspection Equipment Drawing provides a comprehensive overview of a specialized machine designed to ensure the accuracy, quality, and reliability of terminal press-in connections. This equipment is widely used in industries such as automotive, electronics, and industrial manufacturing to maintain consistent product standards.

L'un de ses caractéristiques principales est-ce que c'est high-precision inspection system, which detects misalignments, loose connections, and defects in terminal press-in processes. This ensures product reliability and minimizes the risk of failures in critical applications.

Un autre aspect important est son automated inspection workflow, which reduces the need for manual checks, improves efficiency, and ensures consistent results across high-volume production lines.

Le interface de contrôle conviviale allows operators to monitor inspection parameters, adjust settings, and review results in real time. This simplifies operations and reduces training time for new staff.

De plus, le conception structurelle robuste of the equipment ensures stability and durability during prolonged operations, reducing maintenance requirements and operational downtime.

Le compatibilité polyvalente of the inspection equipment allows it to handle a wide range of connector types and sizes, making it suitable for various production requirements across multiple industries.

En conclusion, le Équipement d'inspection par insertion de connecteurs de bornes is an essential tool for manufacturers seeking to maintain high-quality standards. Its precision inspection capabilities, automation, and durable design make it a reliable choice for modern production lines focused on quality assurance.