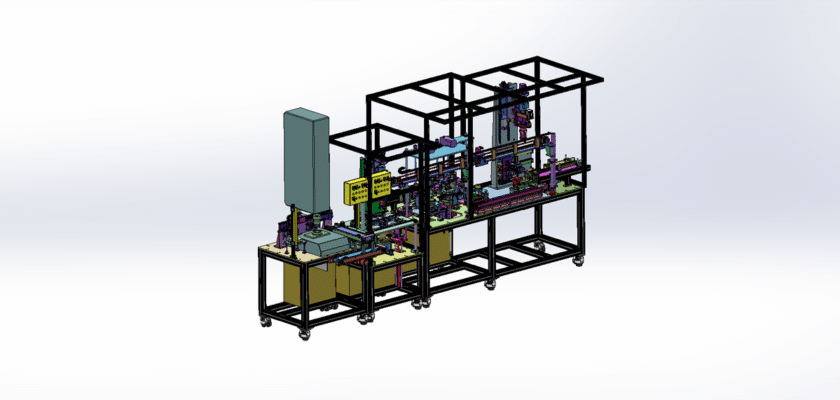

Le Ligne de production de gobelets de détection de fuites par soudage par ultrasons Il s'agit d'un système automatisé avancé conçu pour produire des gobelets de haute qualité, avec des capacités de soudage de précision et de détection des fuites. Cette ligne de production de pointe intègre la technologie de soudage par ultrasons pour garantir des gobelets durables et étanches, ce qui la rend idéale pour les secteurs de l'emballage, de l'agroalimentaire et de la pharmacie.

Caractéristiques principales :

- Technologie de soudage par ultrasons : La ligne de production utilise des ultrasons haute fréquence pour réaliser des soudures rapides et précises. Cette technique génère moins de chaleur que les méthodes de soudage traditionnelles, garantissant une liaison propre et solide sans endommager le matériau.

- Intégration de la détection des fuites : Équipée d'un système avancé de détection des fuites, cette machine vérifie automatiquement l'intégrité des gobelets, identifiant même les plus petites fuites. Cette fonctionnalité garantit que seuls des produits sans défaut arrivent sur le marché, améliorant ainsi le contrôle qualité et réduisant les déchets.

- Production entièrement automatisée : Le système est conçu pour une intégration transparente, offrant un processus de production entièrement automatisé du début à la fin. Cela améliore l'efficacité, réduit les coûts de main-d'œuvre et minimise les risques d'erreur humaine.

- Production à grande vitesse : Grâce à son automatisation avancée et à son soudage de précision, la ligne de production fonctionne à haute cadence, garantissant une production rapide tout en préservant la qualité des produits. Elle est donc parfaitement adaptée aux environnements de production à grande échelle.

- Polyvalent et fiable : La ligne est capable de traiter divers matériaux, garantissant ainsi sa polyvalence dans diverses applications de fabrication. Sa conception robuste garantit sa fiabilité dans les environnements de production continue et exigeante.

Ce Ligne de production de gobelets de détection de fuites par soudage par ultrasons Offre une solution puissante et performante pour la fabrication moderne, garantissant des produits de haute qualité avec un minimum d'arrêts de production. Téléchargez le schéma détaillé pour intégrer dès aujourd'hui cette technologie innovante à votre processus de production !