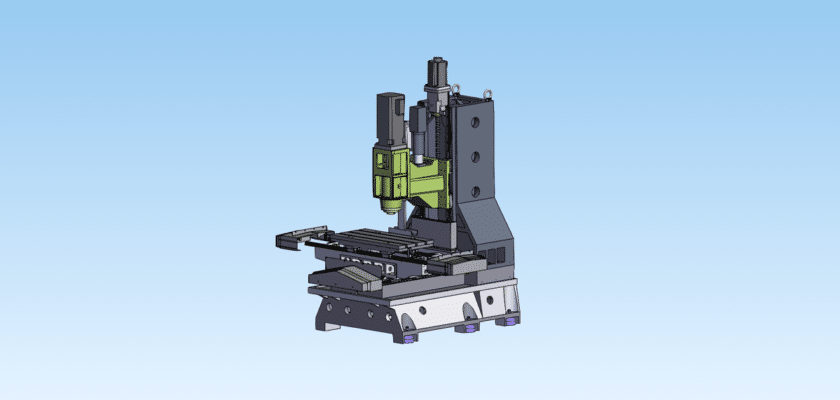

Le V850 Machining Center is widely considered the “sweet spot” of vertical milling, offering a versatile travel envelope that accommodates everything from small precision components to medium-sized automotive parts. This comprehensive engineering drawing provides a detailed look at the structural and mechanical layout of the 850-series VMC. For shops looking to optimize their production, having an accurate technical blueprint is essential for designing custom workholding, planning tool clearances, and integrating robotic loading arms.

This technical document covers the critical X, Y, and Z-axis travel specifications (typically 800x500x500 mm), spindle head assembly, and the tool changer interface. By downloading this drawing, you gain access to the machine’s geometric foundation, including the precision-ground table dimensions and the column’s structural reinforcement. The layout is optimized for high-speed machining, detailing the placement of linear guideways and ball screws that ensure repeatable positioning accuracy. Whether you are troubleshooting a mechanical sub-assembly or performing a full machine calibration, this resource provides the verified data required to keep your V850 running at peak efficiency.

At MechStream, we provide the blueprints that power the world’s machine shops. This industry-standard reference allows you to visualize the internal lubrication paths and cooling channels necessary for maintaining thermal stability during heavy-duty cutting operations. Download this high-fidelity technical asset today to streamline your manufacturing and maintenance workflows.

Caractéristiques principales :

- 800mm X-Axis Working Envelope: Provides detailed dimensions for the table travel, ensuring you can maximize part sizes while avoiding collision zones.

- High-Rigidity Column Design: Engineered to support high-speed spindle rotation while absorbing the cutting forces of aggressive milling passes.

- Standardized T-Slot Table Layout: Precise specifications for the worktable surface, allowing for the rapid design and mounting of specialized jigs and fixtures.

- Integrated Automatic Tool Changer (ATC): Includes technical layouts for the tool carousel and swing-arm mechanisms for lightning-fast tool swaps.

- Advanced Lubrication and Coolant Path: Detailed schematics for internal fluid routing to ensure all moving parts are protected and the workpiece remains cool.