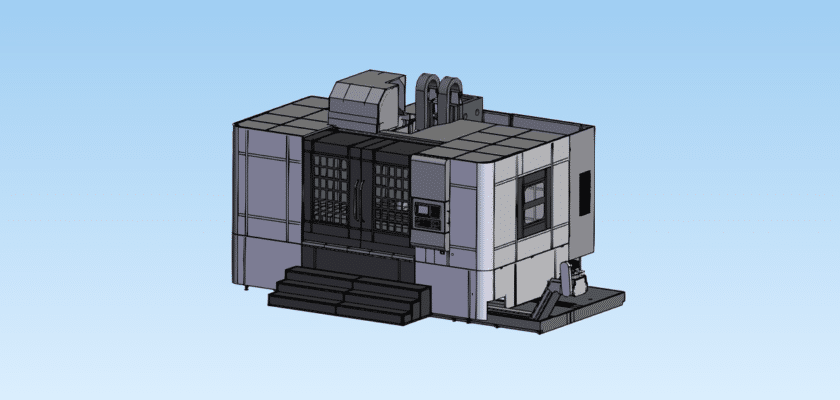

Le Vertical Machining Center V918 represents the pinnacle of high-speed, high-precision milling for the modern production shop. Occupying a strategic position in the mid-size VMC category, the V918 is engineered for shops that require a larger work envelope than a standard 850 model but still demand the agility and rapid traverse speeds of a smaller machine. This comprehensive engineering drawing provides the structural and mechanical blueprints of the V918, detailing the robust column design and the precision-ground table that make this machine a favorite for mold-and-die work and aerospace component manufacturing.

This technical document covers the critical 900x600x600 mm axis travel, spindle torque curves, and the 24-station arm-type automatic tool changer (ATC) interface. By downloading this blueprint, you gain access to the machine’s geometric foundation, including the high-precision linear roller guides and oversized ball screws designed for superior thermal stability. The layout is optimized for high-capacity material removal, featuring detailed schematics for the integrated chip flush system and dual-screw conveyors. Whether you are designing custom multi-part fixtures or planning a robot-loaded automated cell, this resource provides the verified tolerances and mounting geometries necessary for a professional-grade implementation.

At MechStream, we provide the blueprints that help you push the boundaries of productivity. Use this industry-standard reference to understand the V918’s internal lubrication networks and sensor mounting points for real-time condition monitoring. Download this high-fidelity technical asset today and optimize your high-performance machining operations.

Caractéristiques principales :

- Optimized 900mm X-Axis Envelope: Features a generous travel range designed to accommodate larger workpieces or multiple small parts in a single setup.

- Heavy-Duty Spindle Housing: Detailed specifications for a high-rigidity spindle head, balanced for high-RPM finishing and low-frequency heavy roughing.

- Rapid Arm-Type ATC: Includes mechanical layouts for the side-mount tool changer, designed for lightning-fast tool swaps and minimized idle time.

- Roller-Type Linear Guideways: Engineering data for high-load roller guides on all three axes to ensure maximum rigidity and vibration dampening.

- Enhanced Thermal Compensation: Specifically designed with symmetric castings and cooling channels to maintain accuracy throughout long production shifts.