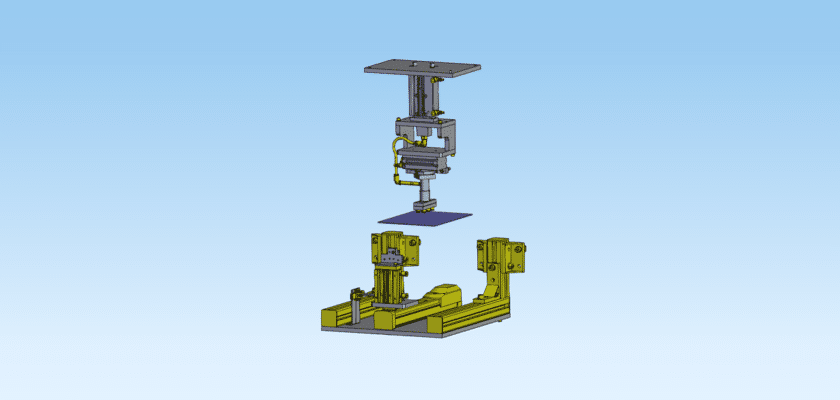

In automated assembly lines, workpieces often arrive in an orientation that is incompatible with the next process. This Workpiece Orientation Change On The Conveyor CAD dessin provides a mechanical blueprint for a “90-degree turner” or “flip mechanism” integrated directly into a transport system. Rather than using expensive robotic arms for simple rotations, this mechanism uses clever geometry and passive or active guides to rotate parts—such as boxes, engine blocks, or PCB trays—as they move along the belt. This ensures the part is perfectly aligned for downstream tasks like barcoding, localized drilling, or final packaging.

By downloading this professional dessin, you gain access to a reliable, low-maintenance design that enhances the flexibility of your conveyor system. The assembly features adjustable guide rails and a specialized turning star or bump-turn block that can be fine-tuned for various workpiece dimensions. This solution is particularly valuable for high-speed lines where stopping the material flow for reorientation would cause significant bottlenecks. The technical files include detailed views of the mounting brackets, pivot points, and low-friction contact surfaces, providing a turnkey engineering resource for your next factory floor upgrade.

Caractéristiques principales :

- Smooth Rotation Geometry: Engineered with optimized curves and pivot points to ensure the workpiece rotates 90 or 180 degrees without slipping or falling off the conveyor.

- Adjustable Part Guides: Features sliding rails that can be quickly moved to accommodate different workpiece widths and lengths, making the line multi-product capable.

- Low-Impact Design: Utilizes high-performance polymers or cushioned contact points to prevent surface damage to delicate or finished products during the turn.

- Passive and Active Options: The CAD model includes details for both passive “bump-turn” layouts and actively powered rotary actuators for more controlled positioning.

- Space-Saving Integration: Designed to be mounted directly onto standard conveyor profiles, requiring minimal modification to existing hardware.