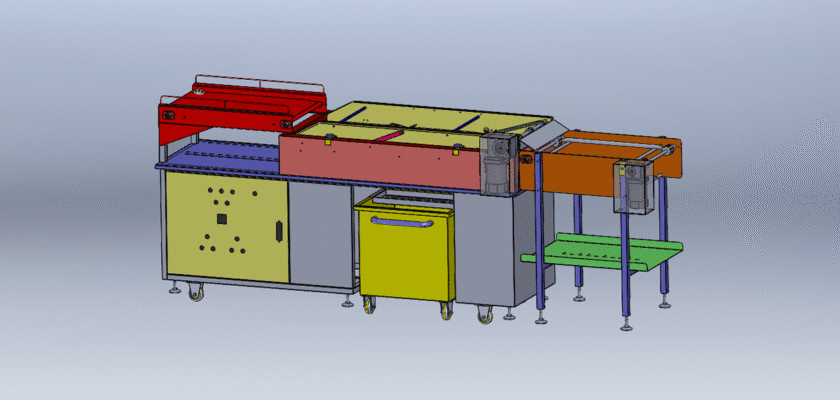

Step up your food processing capabilities with this professional Frying Machine drawing. This detailed technical blueprint is an invaluable resource for food manufacturers, mechanical engineers, and anyone involved in the design and operation of industrial kitchen equipment. An automated frying machine is the cornerstone of high-volume food production, enabling continuous and consistent cooking of a wide range of products, from snacks like chips and pellets to prepared foods like chicken and vegetables. This system eliminates the need for manual batch frying, drastically increasing efficiency and ensuring uniform product quality.

The drawing provides a comprehensive view of a continuous frying system, including the main frying vessel, conveyor belt mechanisms for food transport, and integrated heating and oil filtration systems. It offers a deep dive into the engineering principles of food machinery, such as heat transfer, fluid dynamics, and food-grade material selection. By studying these plans, you can gain a profound understanding of how to design a machine that not only fries food to perfection but also maintains oil quality and reduces energy consumption. This free download is a fantastic opportunity to acquire the technical knowledge to build or improve your own automated frying system, ensuring your production line runs smoothly and profitably.

Key Features:

- Continuous Operation: The design showcases a conveyor system that moves food through a heated oil bath, allowing for uninterrupted production and a massive increase in throughput.

- Oil Filtration System: The blueprint includes a crucial oil filtration mechanism, which removes food particles to extend the life of the cooking oil and maintain product quality.

- Precise Temperature Control: The design incorporates a sophisticated heating system with temperature sensors to ensure the oil remains at the optimal temperature for consistent frying results.

- Energy-Efficient Design: The plans highlight features that promote energy efficiency, such as insulated frying vessels and an optimized heating system to reduce operational costs.