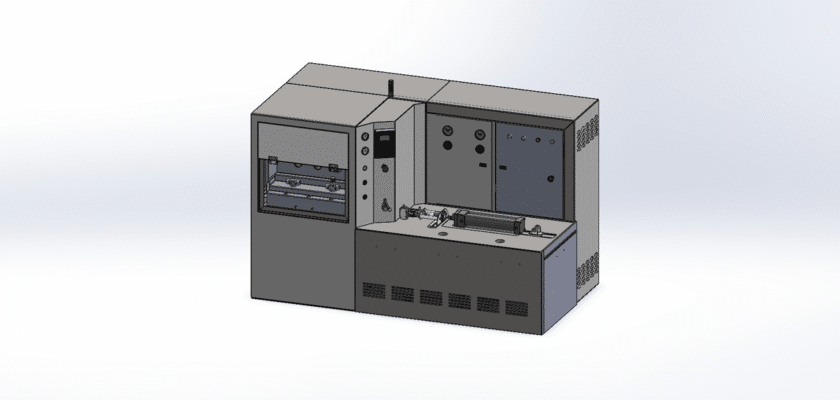

This invaluable technical drawing for a Fully Automatic Pressure Testing Machine is an essential resource for engineers and manufacturers in the automotive, plumbing, and fluid dynamics industries. The comprehensive blueprint provides a detailed look at the design and functionality of a machine that is crucial for verifying the integrity and leak-tightness of components under pressure. This download offers a complete guide to a system that automates the entire testing cycle, from sealing the part to applying the precise pressure and logging the results, all without manual intervention. This drawing is an indispensable tool for professionals seeking to design, build, or integrate a high-performance testing solution into their production lines. By providing a full technical overview of this robust and reliable piece of equipment, this download empowers you to optimize your manufacturing processes, minimize defects, and enhance overall quality control.

Key Features:

- High-Precision Pressure Application: The design is engineered with a sophisticated control system that ensures pressure is applied with exceptional accuracy and consistency, which is critical for product reliability.

- Automated Testing Cycle: The blueprint details a fully automated process that reduces manual labor and human error, ensuring a repeatable and reliable testing procedure for every product.

- Integrated Leak Detection: The design includes provisions for highly sensitive sensors and gauges to detect even minute pressure drops, ensuring the highest level of product integrity.

- Versatile Fixture Design: The design is flexible and can be adapted with interchangeable fixtures to test a wide variety of product shapes and sizes, making it a versatile solution for diverse production lines.

- Data Logging Capability: The design includes provisions for a data logging system, enabling the automatic recording of test results for quality assurance, traceability, and process improvement.