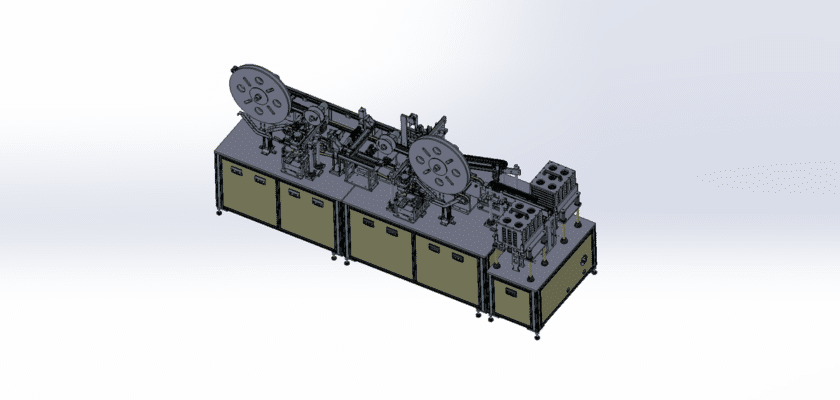

This detailed drawing of the Fully Self-Assembly Line illustrates a cutting-edge system designed for the automated assembly of various components across diverse industries, including automotive, electronics, and consumer goods. Ideal for manufacturers aiming to enhance efficiency and reduce labor costs, this assembly line integrates advanced technologies for streamlined production.

Key Features of the Drawing:

- Fully Automated Assembly Process: The self-assembly line employs sophisticated automation technologies, allowing for seamless integration of multiple assembly stations and reducing manual labor requirements.

- Modular Design: The line features a modular configuration, enabling easy customization and scalability to accommodate various products and production volumes.

- High Precision Component Handling: Equipped with advanced robotics and precision alignment tools, the system ensures accurate positioning and assembly of components, meeting stringent quality standards.

- User-Friendly Control Interface: The intuitive control panel allows operators to monitor and manage the entire assembly process, facilitating quick adjustments for different product specifications.

- Integrated Quality Control Systems: Built-in inspection mechanisms continuously monitor the assembly process, ensuring that each product meets quality standards and minimizing defects.

- Versatile Application Compatibility: Designed to accommodate a wide range of products and materials, making it adaptable for various industries and product lines.

- Robust and Durable Construction: Constructed from high-quality materials, the assembly line is engineered for longevity and reliability, ensuring optimal performance in high-volume production environments.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient self-assembly solutions in their production operations.