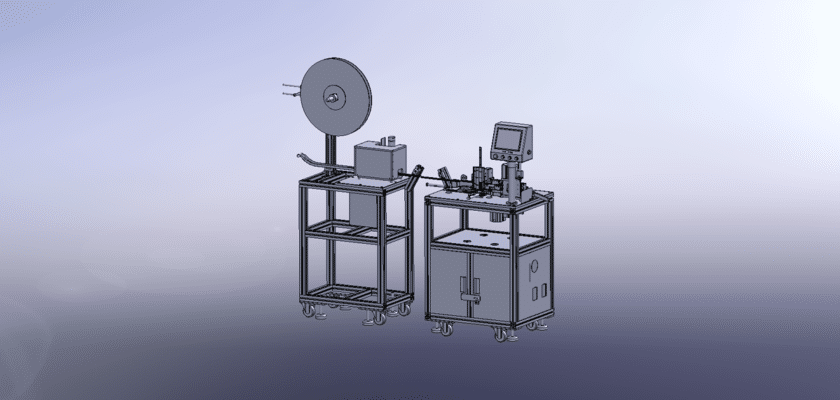

The High-Speed Bending Pin Detection Machine is an advanced automated system designed to detect and inspect bending pins at high speeds with exceptional precision. This machine plays a crucial role in quality control processes, ensuring that pins are correctly formed and meet strict industry standards.

One of the standout features of this detection system is its high-speed performance, enabling rapid inspection without compromising on accuracy. This makes it ideal for industries where efficiency and throughput are critical, such as automotive, electronics, and manufacturing sectors. By detecting defects in real-time, the machine helps prevent the production of defective components, significantly reducing waste and improving overall production efficiency.

The precise detection technology ensures that each pin is inspected thoroughly for any bending or deformations. The system is equipped with advanced sensors that can identify even the smallest deviations, providing reliable feedback to operators. This reduces the risk of defective pins passing through the production line, ensuring that only quality components reach the end users.

Additionally, the user-friendly interface of the machine simplifies operation and minimizes the need for specialized training. The system’s high level of automation also reduces labor costs and human error, streamlining the entire inspection process.

In conclusion, the High-Speed Bending Pin Detection Machine offers an effective, efficient, and reliable solution for ensuring the quality of bent pins in fast-paced production environments. It significantly enhances productivity while maintaining high standards of precision and accuracy.