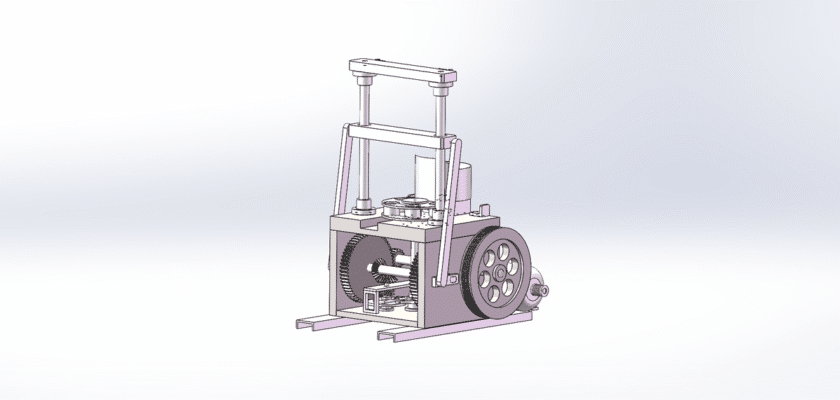

Step into the world of sustainable engineering with our incredible Honeycomb Briquet Machine drawing, now available for free download. This detailed blueprint is an essential resource for engineers, designers, and entrepreneurs in waste management and alternative energy sectors. It provides a comprehensive look into a powerful machine that compresses materials like coal dust, charcoal, or biomass into durable, honeycomb-shaped briquettes. This process is crucial for creating efficient, clean-burning fuel sources and is a key technology in promoting a circular economy. The drawing showcases the machine’s robust design and intricate mechanics, from the feeding system to the high-pressure pressing mechanism and shaping dies. By offering this professional-grade briquet machine drawing, we aim to support innovation and help you build smarter, more sustainable solutions. The plans are fully compatible with most CAD software, allowing you to seamlessly integrate them into your design projects. Download this indispensable resource today and take a significant step toward a greener future.

Key Features:

- High-Pressure Pressing: The drawing details a powerful hydraulic or mechanical press that applies immense force to the raw material, ensuring a dense and structurally stable briquette.

- Honeycomb Shaping Die: It highlights the specialized die assembly that forms the material into a honeycomb shape, which not only increases its surface area for efficient combustion but also allows for better airflow during burning.

- Automated Feeding System: The blueprint outlines an integrated hopper and feeding mechanism that consistently delivers raw material to the pressing chamber, ensuring a continuous and efficient production workflow.

- Robust Frame Construction: The design features a heavy-duty, welded steel frame that provides a stable foundation, minimizing vibration and ensuring the machine can handle high-force operations for an extended lifespan.

- Adjustable Output: The drawing may showcase components that allow for adjustments in briquette size and density, offering versatility for different fuel types and applications.