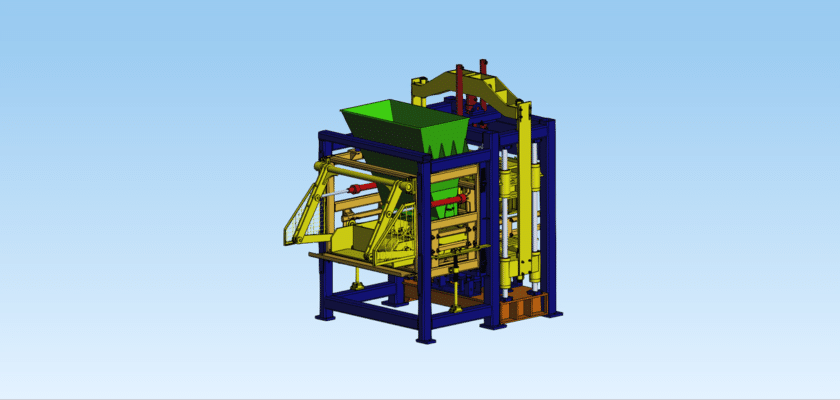

Get instant access to the powerful technical drawing package for a robust Hydraulic Brick Making Machine! MechStream offers these incredible blueprints for download today. This machine is an essential resource for manufacturers in the construction and building materials industry, designed to apply immense hydraulic pressure to compress raw materials (like soil, fly ash, or concrete mix) into dense, high-quality bricks or blocks. The controlled force and repeatable cycle time of this hydraulic system ensure consistent product quality and high output.

Our comprehensive package grants fast access to the full technical specifications of this heavy-duty equipment. The drawing set includes detailed plans for the machine’s primary frame, the hydraulic cylinder assembly, the mold box design, the material hopper interface, and the ejection mechanism. Understanding the force amplification ratio and the precise tolerances of the mold box is key to producing bricks that meet required strength standards. By downloading these ultimate technical files, you gain all the necessary dimensional data, material requirements, and assembly layouts for accurate manufacturing, overhaul, or educational analysis. Stop struggling with inefficient production methods. Download the complete Hydraulic Brick Making Machine drawing today and leverage professional-grade schematics to build a machine capable of high-volume, precision brick production. This resource is indispensable for civil and mechanical engineers in the building sector.

Key Features:

- High-Force Compaction System: Detailed schematics of the main hydraulic cylinder and ram mechanism designed to apply the necessary force for brick density.

- Mold Box and Tooling Plans: Precision dimensional drawings for interchangeable mold cavities to produce various brick shapes and sizes.

- Ejection Mechanism Design: Plans for the auxiliary cylinder or mechanical linkage used to smoothly eject the finished brick from the mold.

- Frame and Support Structure: Structural drawings specifying the steel gauges and joint designs to absorb high cyclic loading.

- Material Feeding Interface: Includes plans for integrating the machine with a hopper or conveyor system for automated material delivery.