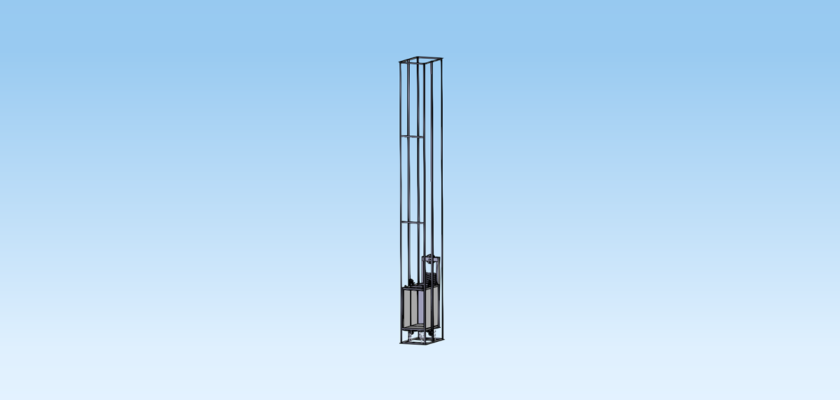

The L-Type Positioner is a specialized piece of automation equipment designed to hold and manipulate workpieces in a way that provides maximum clearance for robotic or manual welding torches. This professional drawing features a distinctive “L” shaped cantilevered frame, which allows the rotation axis to be positioned away from the main support pedestal. This unique geometry is particularly effective for welding bulky or asymmetrical parts, such as cabinets, frames, and tanks, as it minimizes the risk of interference between the welding arm and the positioner’s own structure.

By downloading this comprehensive drawing, you will gain access to a dual-axis motion assembly: a 360-degree rotary table and a tilting arm that can often reach up to 90 degrees or more. The CAD files include precise specifications for the heavy-duty slew drives, the counterbalancing logic required for the cantilevered load, and the reinforced structural base. For engineers designing automated production lines, this positioner provides the high repeatability and rigidity necessary for synchronized motion control, ensuring that every weld bead is placed with surgical precision.

This blueprint is optimized for durability in high-spatter environments. The drawing includes details for integrated grounding paths to protect internal electrical components and the precision-machined faceplate with standard T-slots for fixture mounting. Utilizing this pre-engineered model allows you to skip complex structural calculations for moment loads, providing a verified framework for building a high-performance positioning station that maximizes workplace ergonomics and welding efficiency.

Key Features:

- Cantilevered Motion Geometry: Engineered “L” frame in the drawing that provides 360-degree access to the workpiece without structural obstruction.

- Dual-Axis Synchronized Rotation: Detailed layout for both the tilting and rotating drives, allowing for complex 3D positioning.

- High-Torque Slew Drive Integration: Heavy-duty transmission specifications designed to handle high eccentric loads and moments.

- Integrated Safety Grounding: Strategic electrical conduction paths designed to prevent welding current from damaging bearings.

- Modular Mounting Interface: A precision faceplate design with universal T-slots for the rapid installation of custom clamping fixtures.