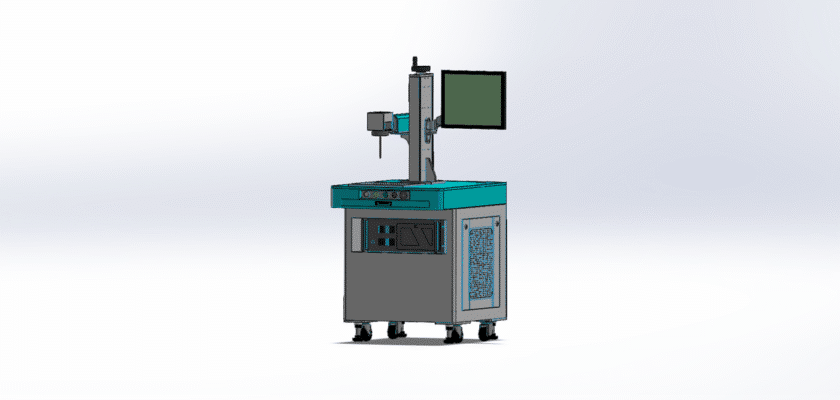

The laser marking machine is a revolutionary piece of equipment used for creating permanent, high-quality marks on a vast array of materials, including metals, plastics, wood, and glass. Unlike traditional methods that use ink or physical stamps, laser marking employs a concentrated beam of light to alter the surface of a material, resulting in durable, non-fading marks. This technology is indispensable across industries such as aerospace, automotive, medical, and electronics, where traceability and branding are paramount. Our free engineering drawings provide a comprehensive look at the sophisticated design and intricate components that make this machine so precise and efficient.

The drawing package is perfect for students, engineers, and designers who wish to understand the principles of laser-material interaction. It includes detailed schematics of the laser source, the galvo scanner system for beam guidance, and the focusing optics that converge the laser beam to a tiny spot. The blueprints illustrate how the machine operates without contact, which is crucial for marking delicate or sensitive components. By downloading these professional-grade drawings, you’ll gain valuable insights into a technology that is shaping modern manufacturing and ensuring product integrity.

Key Features:

- Diverse Applications: The drawings show a versatile machine capable of various marking processes, including annealing, etching, and engraving, which can be adapted for different materials and desired effects.

- Precision and Speed: The design highlights the use of high-speed galvo mirrors and a focused laser beam, allowing for rapid and precise marking of intricate details like serial numbers, barcodes, and logos.

- Non-Contact Operation: The blueprints demonstrate a non-contact process that prevents damage to the product, making it ideal for marking sensitive components and finished goods.

- Durability and Permanence: The drawings provide insight into a system that creates marks resistant to abrasion, heat, and chemicals, ensuring traceability and product authentication for the lifetime of the part.

- Integration and Automation: The design is shown to be easily integrated into existing production lines, with provisions for automated loading and unloading, showcasing its role in streamlined manufacturing.