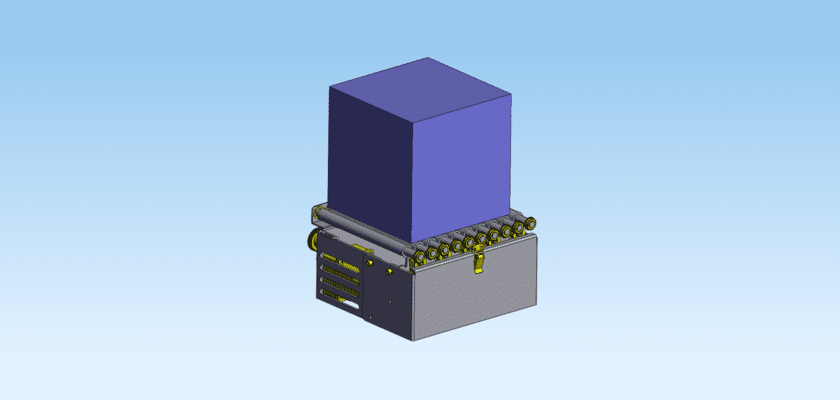

Maximize the precision of your material flow with our professional Lock-Type Conveyor Belt Loading and Unloading Mechanism drawing. Standard conveyors are excellent for transport, but they often struggle with “singulation”—the process of separating and stopping individual workpieces for a specific operation. This technical CAD resource provides a blueprint for a high-performance mechanical “lock” or escapement system. By downloading this file, you gain access to a design that allows you to pause a workpiece at a precise station while the conveyor belt continues to slide beneath it, ensuring seamless integration with robotic arms or inspection sensors.

The engineering focus of this design is the synchronized “gate” system. The drawing includes detailed views of the primary stop-gate (which halts the workpiece) and the secondary separator-gate (which holds back the following queue). By utilizing this blueprint from MechStream, you can prevent “line pressure” buildup, where the weight of multiple workpieces pushes against the one being processed, potentially causing damage or misalignment. This is a vital asset for designers of electronic assembly lines, bottling plants, and automotive component testing cells.

Our technical documentation prioritizes smooth actuation and workpiece integrity. The assembly is designed with low-friction bumpers and soft-touch contact points to prevent marring or scratching of delicate parts. Whether you are building a manual loading station or a fully automated unloading buffer, this drawing provides the exact geometric relationships, pneumatic timing requirements, and sensor mounting patterns needed for a professional-grade material handling interface.

Key Features:

- Dual-Gate Escapement Logic: Precisely controls the entry and exit of one part at a time, preventing jams and double-loading.

- Low-Friction Slide Contact: Features specialized materials on the locking fingers to reduce wear on the conveyor belt and the workpiece.

- High-Speed Pneumatic Actuation: Detailed specifications for compact air cylinders and flow control valves to achieve rapid cycle times.

- Adjustable Workpiece Widths: Designed with modular mounting slots, allowing the locking arms to be repositioned for different product sizes.

- Integrated Proximity Sensing: Includes pre-defined mounts for inductive or optical sensors to verify part presence before the gate opens.