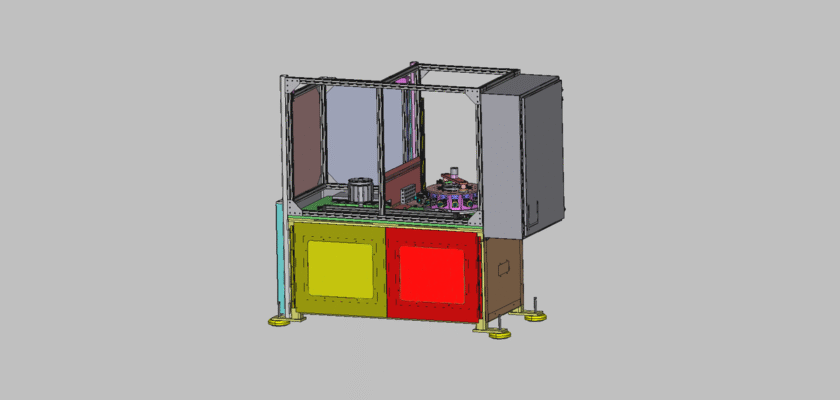

Elevate your manufacturing capabilities with our free Magnet Automated Assembly Equipment drawing. This comprehensive CAD file is an indispensable resource for engineers, designers, and manufacturers working in the robotics, electronics, and automotive industries. This detailed blueprint provides a complete look at a specialized machine designed to automate the precise and secure assembly of magnets into various components, such as electric motors, sensors, and actuators.

The drawing highlights the complex interplay of robotic arms, specialized grippers, and demagnetizing systems required to handle and place powerful magnets safely and accurately. By automating this process, manufacturers can achieve superior product quality, reduce cycle times, and minimize the risk of damage to delicate components and magnets. Whether you are building a new assembly line, upgrading existing equipment, or simply want to understand the mechanics of advanced industrial automation, this resource provides the technical insights you need. It’s a perfect tool for students and professionals alike, offering a detailed glimpse into the future of high-precision manufacturing.

Key Features:

- Robotic Precision: The drawing illustrates the use of robotic end-effectors and grippers designed for the delicate and precise handling of magnets.

- Component Handling: Details the automated systems for demagnetizing, orienting, and loading magnets into the assembly head to prevent attraction-related issues.

- Integrated Systems: Highlights the seamless integration of adhesive dispensing systems to ensure a secure bond after magnet placement.

- Workflow Optimization: The blueprint is a great tool for understanding how to optimize a machine’s layout for high-speed, efficient, and repeatable assembly.

- Technical Specifications: Includes critical dimensions and specifications for the machine’s components, making it suitable for design and reference purposes.