A medical capsule bottle filling machine is a vital piece of equipment in the pharmaceutical and nutraceutical industries, designed to automate the process of counting and dispensing capsules into bottles. These machines ensure high-speed, accurate, and hygienic packaging, which is critical for maintaining product integrity and regulatory compliance. They streamline the entire production line, from the initial capsule supply to the final capped bottle, significantly increasing efficiency and reducing the risk of human error.

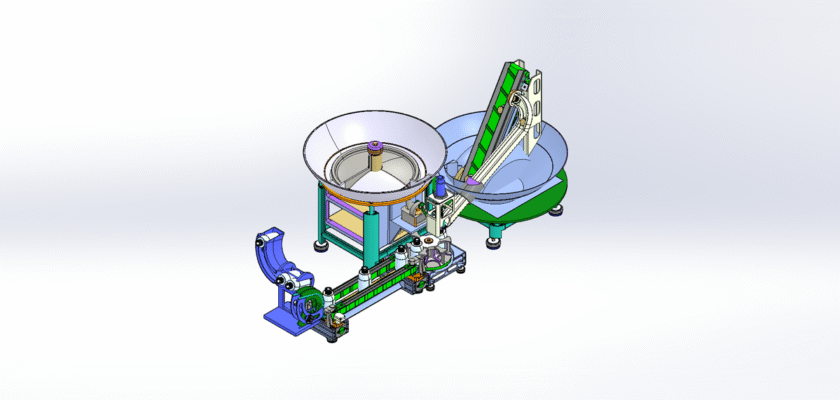

The machine’s working principle involves a series of automated steps. First, a hopper feeds empty capsules into the system. A sorting mechanism then correctly orients and feeds the capsules one by one into the counting channels. Using advanced sensors, the machine counts the capsules with exceptional accuracy before dropping the precise number into a waiting bottle. This bottle is then moved along a conveyor to the next stations for capping and sealing. The entire process is controlled by a PLC (Programmable Logic Controller) system, which allows for precise adjustments and monitoring to ensure consistent quality and output.

Key Features:

- High-Speed & Precision Counting: The machine is engineered with advanced photoelectric sensors to count capsules with incredible accuracy, minimizing waste and ensuring uniform dosage per bottle. It can process thousands of capsules per hour, making it ideal for large-scale production.

- GMP & Hygiene Compliance: Constructed from high-grade stainless steel and designed with a fully enclosed system, the machine meets stringent Good Manufacturing Practices (GMP) and hygiene standards, preventing contamination and ensuring a sterile environment.

- Versatile and User-Friendly: This design is adaptable to various capsule sizes and bottle types, offering flexibility for different product lines. An intuitive touchscreen interface simplifies operation, allowing for quick adjustments and minimal training time for operators.

- Automated and Efficient Workflow: The system automates multiple stages of the filling process—from unscrambling bottles to inserting desiccants, counting capsules, and capping—creating a seamless and highly efficient production line with minimal manual intervention.

- Reliable and Low Maintenance: With a robust mechanical design and integrated self-diagnostics, the machine offers high reliability and durability. Its modular components are easy to disassemble for cleaning and maintenance, ensuring consistent performance and a long operational lifespan.