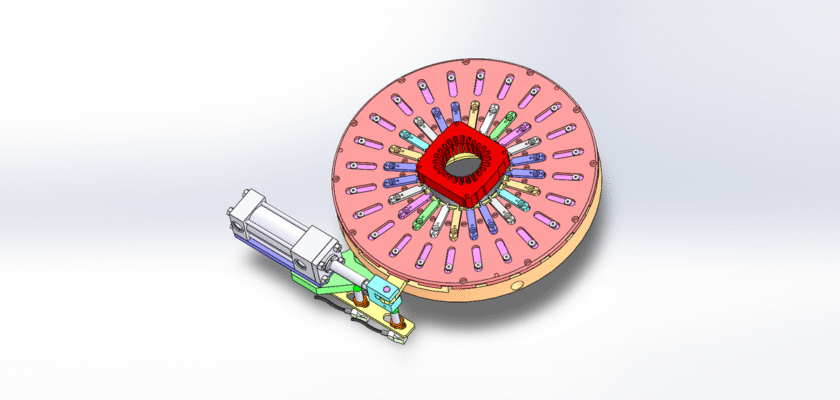

A motor coil winding machine is a specialized piece of equipment used to precisely wind coils of wire onto a stator or armature. This intricate process is fundamental to manufacturing electric motors, generators, and transformers, as the performance and efficiency of the final product are directly dependent on the accuracy and quality of the winding. The machine automates the manual, labor-intensive task of winding wire, ensuring uniform tension, consistent turns, and proper wire placement within the slots. This automation significantly increases production speed, reduces manufacturing errors, and improves the overall reliability of the electric motor. The sophisticated control systems on these machines allow for a variety of winding patterns and specifications to be programmed, making them highly versatile for producing different types of motors.

Our free motor coil winding machine drawing provides a valuable resource for electrical engineers, machinery designers, and students interested in the inner workings of industrial automation. This detailed drawing set offers a clear understanding of the mechanical and electrical components that work in harmony to create the heart of an electric motor.

Key Features:

- High-Precision Control: The drawings highlight the servo-driven systems and programmable logic controllers (PLCs) that ensure precise wire placement and tension, crucial for optimal motor performance.

- Automated Operation: The design illustrates how the machine handles wire feeding, winding, and cutting automatically, minimizing human intervention and maximizing production efficiency.

- Versatile Tooling: The plans show the modular tooling and interchangeable winding heads that allow the machine to adapt to various stator sizes and coil configurations.

- Robust Construction: The design emphasizes the sturdy frame and high-quality components necessary to withstand the continuous, high-speed operation required in a manufacturing environment.