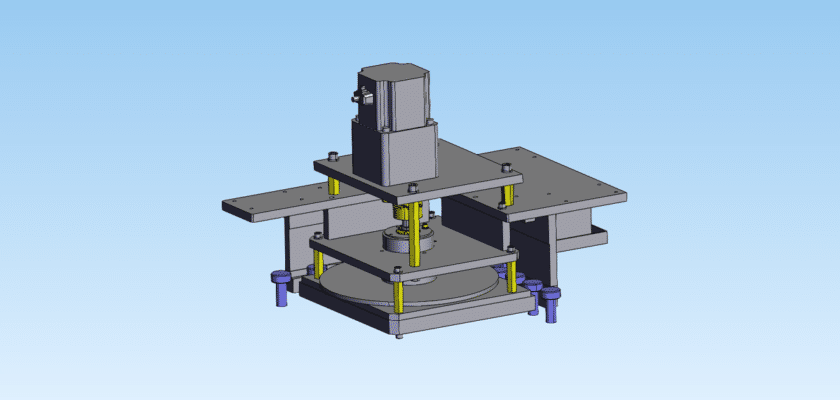

Minimize product waste and prevent line stoppages with our professional Packet Recovery Mechanism drawing. In high-volume packaging, a percentage of packets will inevitably fail inspection due to weight variance, seal integrity, or improper labeling. This technical CAD resource provides a blueprint for a high-speed Air-Blast or “Flipper” Diverter that removes these sub-standard packets from the main stream without slowing down the line. By downloading this file from MechStream, you gain access to a design that gently transitions rejected packets into a recovery bin, preserving the product for potential manual rework or re-insertion.

The design featured in this package focuses on Low-Impact Handling and High-Frequency Response. The drawing includes detailed layouts for ultra-lightweight carbon fiber or aluminum arms and high-speed solenoid valve integration. A major challenge in packet recovery is the “sailing” effect of lightweight flexible pouches; by utilizing this blueprint, you can implement a design featuring vacuum-assisted chutes or overhead guides that maintain control of the packet even at speeds exceeding 200 units per minute. This is an essential asset for manufacturers of pharmaceutical sachets, food condiment packets, and cosmetic samples.

Our technical documentation prioritizes hygiene and rapid cleaning (Washdown capability). The assembly is designed with smooth, crevice-free surfaces and FDA-compliant materials (316 Stainless Steel and food-grade polymers). Whether you are building a reject gate for a checkweigher or a recovery system for a multi-lane sachet filler, this drawing provides the exact sensor-trigger timing logic, pneumatic pressure requirements, and bin-full sensing paths required for a professional-grade installation.

Key Features:

- Millisecond Response Time: Engineered for ultra-fast actuation to ensure only the specific “failed” packet is removed without disturbing the adjacent “good” product.

- Non-Damaging Recovery Path: Detailed designs for sloped, low-friction chutes that prevent the packet from bursting or the seal from rupturing during the diversion process.

- Modular Lane Integration: Includes blueprints for compact “over-the-belt” mounts that can be retrofitted to existing conveyor systems with minimal downtime.

- Dual-Action Diverter Options: Features both “Blow-Off” (air jet) and “Positive-Action” (mechanical arm) configurations to suit different packet weights and textures.

- Integrated Batch Counting: Pre-defined mounting for photo-electric sensors to track the number of rejected packets for real-time Yield Analysis.