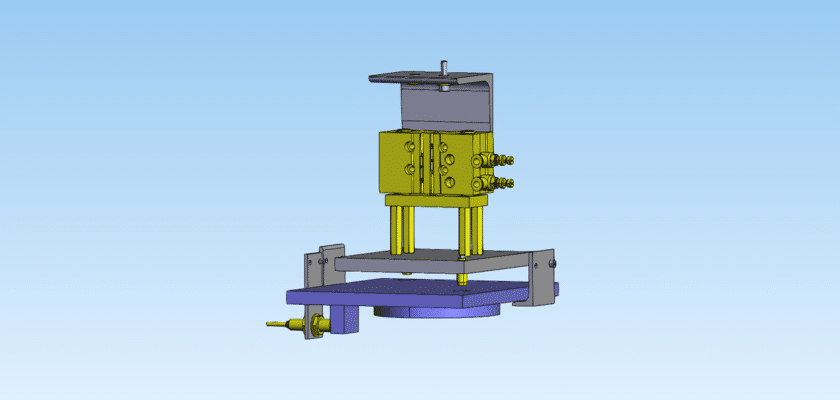

Eliminate positional drift and ensure sub-millimeter accuracy with our professional Pallet Positioning Mechanism drawing. In a standard conveyor system, pallets often have significant “play” to allow for smooth travel; however, once the pallet reaches a process station, it must be rigidly and accurately locked into place. This technical CAD resource provides a blueprint for a Lift-and-Locate or Shot-Pin architecture. By downloading this file from MechStream, you gain access to a design that decouples the pallet from the moving conveyor belt and references it against high-precision mechanical datums.

The design featured in this package focuses on Repeatable Geometric Constraint. The drawing includes detailed layouts for tapered locating pins and matching hardened bushings. When the pallet arrives at the station, the mechanism engages these pins into the pallet’s base, correcting for X, Y, and Theta (rotational) errors simultaneously. By utilizing this blueprint, you can ensure that your robotic grippers, screwdrivers, or vision systems are always interacting with the workpiece at the exact same coordinates. This is an essential asset for designers of powertrain assembly lines, electronics testing stations, and battery manufacturing modules.

Our technical documentation prioritizes rigidity and sensor feedback. The assembly is designed with integrated “Position Seated” sensors to verify that the pallet is fully engaged before the process begins. Whether you are building a simple manual workstation or a high-speed synchronous transfer line, this drawing provides the exact pin tolerances ($g6/H7$), pneumatic cylinder sizing, and material specifications required for a professional-grade, high-durability installation.

Key Features:

- Tapered Pin Alignment: Engineered with hardened steel pins and bushings to provide centering and locking in a single, smooth stroke.

- Conveyor Decoupling: Detailed designs for a “lifting” action that raises the pallet slightly off the belt, preventing vibration and belt wear during processing.

- Three-Point Datum Logic: Based on the 3-2-1 principle of mechanical constraint to ensure unambiguous positioning in the XYZ planes.

- High Locking Force: Features robust pneumatic or hydraulic actuation to resist lateral forces from heavy-duty operations like drilling or press-fitting.

- Modular “Station Base” Design: Provides a universal mounting framework that can be easily integrated into standard T-slot aluminum profiles or structural steel frames.