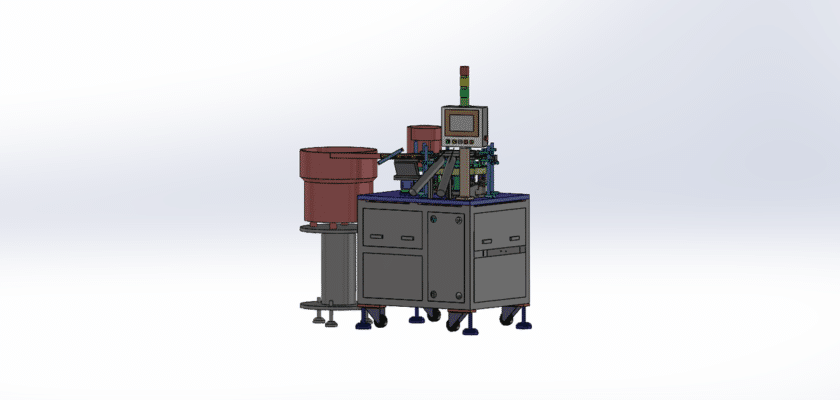

This detailed drawing of the Perfume Spray Head Pump Core Seal Ring Assembly Machine illustrates a specialized system designed for the automated assembly of spray head components, specifically focusing on the core and seal ring integration. Ideal for the cosmetics and fragrance industries, this machine enhances production efficiency while ensuring high-quality assembly.

Key Features of the Drawing:

- Automated Assembly Process: The machine utilizes advanced automation technology to streamline the assembly of spray head components, significantly increasing throughput and reducing manual labor.

- Precision Alignment Mechanism: Equipped with high-accuracy fixtures and alignment tools, the system ensures that core and seal ring components are precisely positioned and securely assembled, minimizing the risk of defects.

- User-Friendly Control Interface: An intuitive control panel allows operators to easily configure settings, monitor assembly processes, and make quick adjustments for different spray head designs.

- Robust and Durable Construction: Built from high-quality materials, the machine is designed for longevity and reliability, ensuring consistent performance in high-volume production environments.

- Integrated Quality Control Features: Continuous monitoring systems check the integrity of each assembly, ensuring that every spray head meets stringent quality standards.

- Versatile Application Compatibility: Capable of accommodating various spray head designs and configurations, the machine is adaptable for diverse applications within the fragrance and cosmetic sectors.

- Efficient Material Handling: The design may include automated feeding and alignment systems to streamline the assembly process, enhancing overall operational efficiency.

This drawing serves as a vital reference for engineers and manufacturers seeking effective and efficient solutions for the assembly of perfume spray head pump components in their production lines.