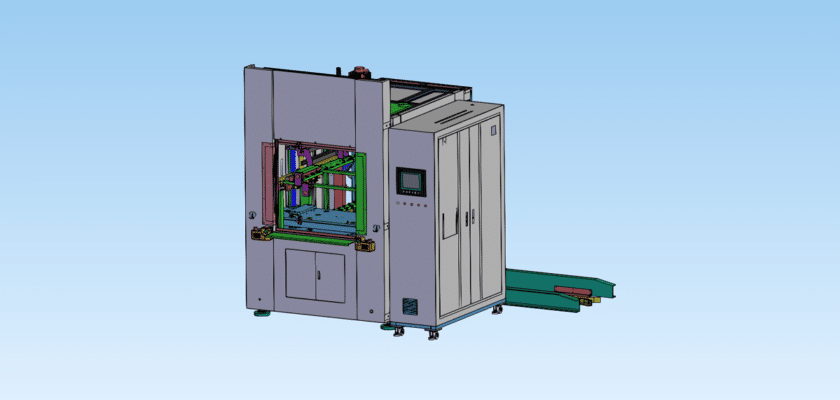

MechStream is your dedicated hub for free mechanical drawing downloads, and we are proud to offer this valuable collection for the Pneumatic Plastic Hot Melt Welding Machine. This specialized equipment is widely used for assembling plastic components, particularly in consumer electronics, automotive parts, and toy manufacturing, where rapid, strong, and clean bonds are crucial. The machine utilizes compressed air (pneumatics) to precisely control the joining force and movement, while a heated platen or tooling melts the plastic surfaces before they are fused under pressure. This combination provides excellent control and repeatability in the welding process.

Downloading these essential drawings offers engineers, technicians, and maintenance staff a powerful resource for understanding and servicing this integrated machinery. The documents detail the precise mechanical linkage, the pneumatic cylinder and valve systems, the heating element placement, and the control circuitry necessary for accurate temperature and pressure management. Access to these high-quality blueprints will dramatically assist in system troubleshooting, fixture design, or machine customization. Don’t delay—download these amazing technical plans immediately and gain the competitive edge in your plastic assembly operations with this critical engineering data.

Key Features:

- Pneumatic System Layout: Includes detailed drawings of the air preparation unit, solenoid valves, and the main pneumatic cylinder responsible for the welding action and clamping force.

- Heating Element Design: Provides precise placement and wiring schematics for the hot melt platen or tooling, ensuring uniform heat distribution for optimal plastic melting.

- Temperature Control Circuitry: Features diagrams of the sensors (thermocouples) and controllers necessary for maintaining the exact welding temperature required for different plastic polymers.

- Mechanical Fixturing Details: Offers blueprints for the customized jigs and fixtures that accurately hold the plastic parts during the heating and welding cycle, ensuring alignment.

- Rapid Cycle Operation: The documents highlight the design elements that allow the machine to perform quick, automated welding cycles, crucial for high-volume production efficiency.