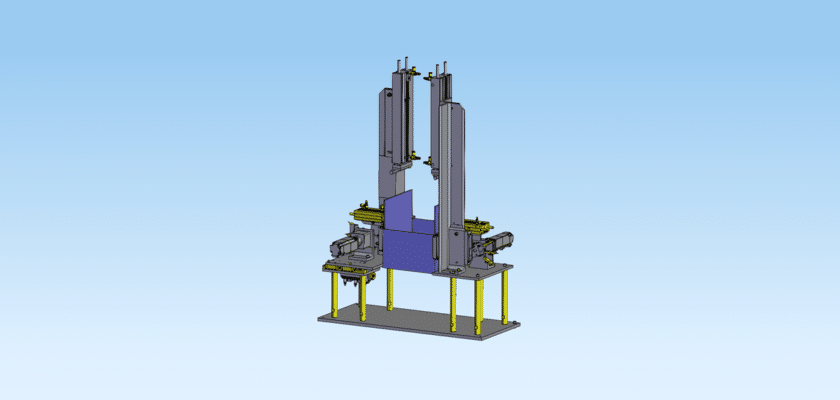

Optimize your machine flexibility with our professional Pressure Block Position Change Adjustment Mechanism drawing. In manufacturing processes like heat sealing, stamping, or lamination, the “pressure block” must be perfectly aligned with the workpiece. If the product size changes, the block’s position must follow. This technical CAD resource provides a blueprint for an Infinite Adjustment Carriage designed to move heavy pressure blocks with micrometer precision. By downloading this file from MechStream, you gain access to a design that allows for rapid vertical or lateral repositioning without compromising the structural rigidity required for high-force applications.

The design featured in this package focuses on Zero-Backlash Locking. The drawing includes detailed layouts for a heavy-duty dovetail or profile rail slide driven by a fine-thread lead screw. A major challenge in adjustable pressure systems is “creep”—where the block shifts under load. By utilizing this blueprint, you can implement a design featuring a secondary mechanical wedge lock or a pneumatic brake that secures the block once the desired position is reached. This is an essential asset for designers of labeling machines, ultrasonic welders, and sheet metal hemming tools.

Our technical documentation prioritizes repeatability and ease of use. The assembly is designed with integrated scales and verniers, allowing operators to return to specific “recipe” settings in seconds. Whether you are building a manual hand-cranked adjustment or a motorized servo-driven system, this drawing provides the exact thread pitches, load-bearing calculations, and gib-strip adjustment procedures required for a professional-grade, high-stiffness installation.

Key Features:

- High-Load Lead Screw Drive: Engineered with ACME or ball-screw threads to provide high mechanical advantage for lifting or lowering heavy blocks.

- Positive Mechanical Locking: Detailed designs for “clamp-on-rail” features that ensure the block becomes a rigid part of the frame during the pressing cycle.

- Digital or Analog Readout: Pre-defined mounting for digital scales or dial indicators to achieve $0.01\text{ mm}$ positioning accuracy.

- Self-Leveling Swivel Joint: Includes a blueprint for a spherical seat or “wobble-plate” interface that ensures the pressure block remains parallel to the workpiece even if the frame deflects slightly.

- Modular Mounting Flange: Features a universal bolt pattern that allows various shapes of pressure blocks (flat, contoured, or textured) to be swapped out quickly.