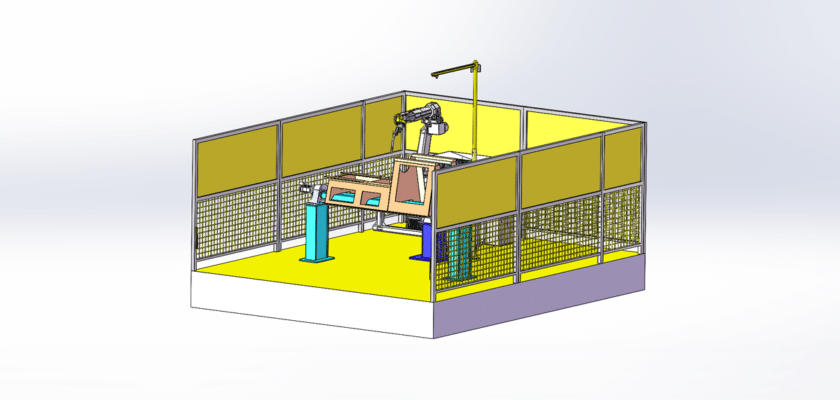

A Prospecting Machine Frame Robot Welding Workstation Drawing is a detailed technical illustration that depicts the design, components, and functionalities of a robotic welding workstation specifically tailored for fabricating machine frames used in prospecting and mining applications. This drawing is essential for engineers, operators, and technicians involved in the design, operation, and maintenance of robotic welding systems.

Principais recursos:

- Layout geral: A comprehensive view of the welding workstation, showcasing its arrangement within a manufacturing environment, including the positioning of the robot, workpieces, and auxiliary equipment.

- Robotic Arm Structure: Detailed illustrations of the robotic welding arm, including:

- Links and Joints: Information about the individual segments (links) and types of joints (revolute, prismatic) that allow for flexible movement and precise welding.

- Degrees of Freedom: Specifications indicating the range of motion that enables the robot to reach various welding positions effectively.

- Welding Tooling: Descriptions of the equipment used for welding, including:

- Welding Torch or Electrode: Information on the design and functionality of the welding tool, such as MIG, TIG, or spot welding equipment.

- Workpiece Fixtures: Details on fixtures used to securely hold machine frames in position during welding.

- Sistema de controle: Details about the control unit that manages the robot’s operations, including:

- Robot Controller: Information on the controller used for programming and executing welding tasks.

- Interface do usuário: Illustrations of control panels or software interfaces that allow operators to program welding parameters and monitor performance.

- Recursos de segurança: Information on safety mechanisms, such as:

- Protective Barriers: Descriptions of safety enclosures and light curtains to protect operators from welding arcs and sparks.

- Sistemas de parada de emergência: Details on emergency stop buttons and monitoring systems to ensure safe operation.

- Fonte de energia: Information about the power source, including:

- Electrical Specifications: Details on the type and capacity of power supply used for the welding equipment and robot.

- Mobility and Positioning: Information on the robot’s base and any mobility features, including:

- Stationary or Mobile Base Design: Diagrams showing the stability of the robot during operation, with options for fixed or movable setups.

- Cooling Systems: Details on any cooling mechanisms used to regulate the temperature of the welding equipment or the work area, ensuring consistent operation and safety.

- Sensors and Feedback Systems: Diagrams showing integrated sensors that provide feedback on the welding process, such as:

- Heat Sensors: Used for monitoring temperature during welding.

- Position Sensors: For ensuring accurate placement of the welding tool relative to the workpiece.

- Pontos de acesso de manutenção: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of the robot and welding equipment.

- Especificações de desempenho: Summary of key performance metrics, such as welding speed, precision, and material compatibility, providing essential information for operational planning.

- Contexto da aplicação: Brief descriptions of typical applications for the welding workstation in the prospecting and mining industry, highlighting its role in fabricating durable frames for machinery.

This drawing serves as a crucial reference for anyone involved in the operation and maintenance of robotic welding workstations for machine frame fabrication, ensuring effective performance, reliability, and adherence to industry standards in manufacturing automation.