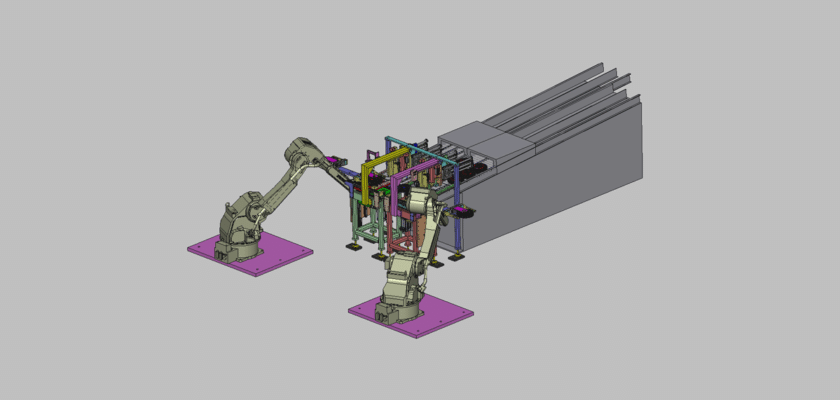

A Robot Assembly Line Drawing is a detailed technical illustration that depicts the layout, components, and workflow of a robotic system designed for assembly line operations. This drawing is essential for engineers, operators, and technicians involved in the design, operation, and maintenance of automated assembly systems.

Principais recursos:

- Layout geral: A comprehensive view of the entire assembly line, showcasing the arrangement of robots, workstations, and conveyor systems within the production environment.

- Robotic Workstations: Detailed illustrations of each robotic station, including:

- Braços Robóticos: Descriptions of the robotic arms used at various stations, highlighting their degrees of freedom and end effectors designed for specific tasks (e.g., assembly, welding, or packaging).

- Efetores finais: Information on the tools or grippers attached to the robots, detailing their functionalities and interchangeability based on assembly requirements.

- Sistema de transporte: Diagrams illustrating the conveyor system that transports components and products along the assembly line, including:

- Types of Conveyors: Information on the types of conveyor belts (e.g., roller, belt-driven) and their configurations.

- Speed and Control Mechanisms: Details on how conveyor speed is controlled and synchronized with robotic operations.

- Sistemas de Controle: Information about the central control unit managing the entire assembly line, including:

- Controladores Lógicos Programáveis (CLP): Descriptions of PLCs used for coordinating robot movements and conveyor operations.

- Interface do usuário: Illustrations of control panels or software interfaces that allow operators to monitor and adjust the production process.

- Recursos de segurança: Information on safety mechanisms throughout the assembly line, such as:

- Sistemas de parada de emergência: Details on emergency stop buttons accessible along the line.

- Protetores e sensores de segurança: Information on protective barriers, light curtains, and sensors designed to prevent accidents and ensure safe operation.

- Material Handling Systems: Descriptions of systems used to transport materials to and from the assembly line, including:

- Automated Guided Vehicles (AGVs): Diagrams showing the use of AGVs for moving components between stations.

- Storage Systems: Information on automated storage solutions integrated into the assembly line.

- Quality Control Stations: Illustrations of quality control checkpoints within the assembly line, detailing:

- Inspection Robots: Information on robotic systems used for inspecting components and finished products.

- Equipamento de teste: Descriptions of any testing apparatus used to ensure product quality.

- Pontos de acesso de manutenção: Guidance on areas designed for easy access during maintenance and repair, facilitating efficient servicing of robots and equipment.

- Especificações de desempenho: Summary of key performance metrics, such as production speed, cycle time, and operational efficiency, providing essential information for planning and optimization.

- Contexto da aplicação: Brief descriptions of typical industries and applications for the robotic assembly line, highlighting its versatility in manufacturing sectors such as automotive, electronics, consumer goods, and more.

This drawing serves as a critical reference for anyone involved in the design, operation, and maintenance of robotic assembly lines, ensuring effective performance, reliability, and adherence to industry standards in automated manufacturing.