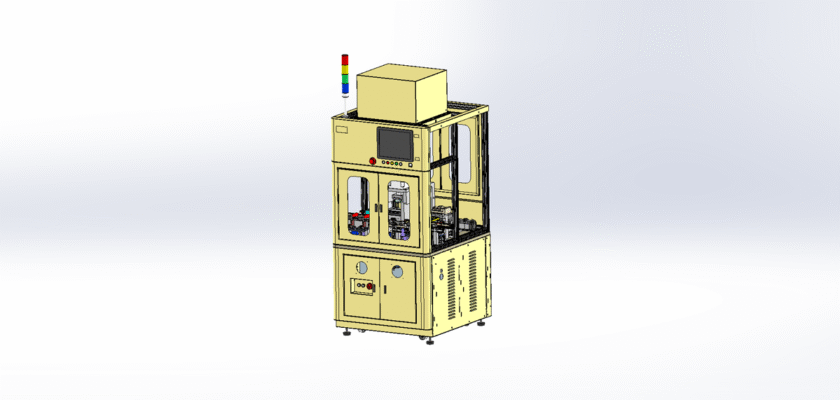

Revolutionize your production with our exclusive Customized Automatic Assembly Machine drawing, available for download gratuito! This comprehensive technical blueprint provides an in-depth look at a sophisticated automated system designed for high-speed, repeatable assembly tasks. This drawing is an invaluable asset for engineers, manufacturers, and students who want to understand the complex integration of robotics, mechatronics, and control systems. It provides detailed schematics of the machine’s structural frame, robotic arms, feeding mechanisms, and programmable logic controller (PLC). By downloading this drawing, you will gain crucial insights into how a machine can be designed to handle multiple assembly steps with incredible precision and speed, drastically reducing labor costs and human error. Whether you’re a professional looking to optimize your factory floor or a student studying advanced manufacturing, this drawing is a perfect starting point.

Principais recursos:

- Modular and Flexible Design: The drawing highlights a modular architecture that allows the machine to be customized for different products and assembly sequences. This flexibility makes it an incredibly versatile solution for various industries, from electronics to medical devices.

- Precision Robotics and Grippers: The blueprint showcases the robotic arm’s design, which is equipped with specialized grippers and end-effectors. This section details how these components are engineered to pick, place, and fasten small parts with sub-millimeter accuracy, ensuring perfect assembly every time.

- Automated Feeding Systems: The drawing includes detailed plans for various part-feeding mechanisms, such as vibratory bowls and linear feeders. These systems are critical for continuously supplying components to the assembly area, ensuring uninterrupted production flow and maximizing efficiency.

- Integrated Sensor and Vision Systems: The schematics illustrate how sensors and cameras are integrated into the machine to monitor each step of the assembly process. This real-time feedback loop allows the system to make adjustments, detect defects, and ensure a high-quality final product.