Ensure the precision and longevity of your automotive and industrial machinery with this comprehensive Flywheel Runout Test Equipment drawing. Flywheel runout is the measurement of how “true” the flywheel’s face and bore are as they rotate. Excessive runout, even a few thousandths of an inch, can lead to severe issues like clutch chatter, premature clutch wear, vibration, and even catastrophic component failure. This critical test is essential for mechanics, engine builders, and quality control professionals to ensure that the flywheel is mounted correctly and is within specified tolerances. This drawing provides a detailed blueprint for a specialized tool designed to accurately measure both axial (face) and radial (bore) runout.

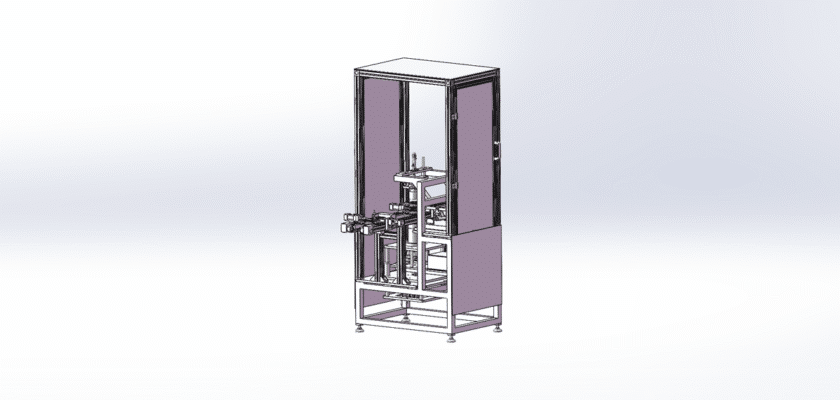

The drawing set includes meticulously detailed plans for building a jig or fixture that mounts a dial indicator to the engine block or bell housing. This setup allows for precise measurement as the flywheel is rotated, giving you a clear and quantifiable result. By using this tool, you can diagnose existing problems, confirm the proper installation of a new or resurfaced flywheel, and prevent costly repairs down the line. It is an indispensable resource for anyone who values precision and wants to ensure the smooth and reliable operation of their machinery. This free download is the perfect opportunity to acquire the knowledge and plans necessary to construct your own professional-grade flywheel testing equipment.

Principais recursos:

- High-Precision Measurement: The design details a system for accurately measuring flywheel face and bore runout, which is critical for preventing drivetrain vibrations and component wear.

- Dial Indicator Integration: The blueprint shows how to securely mount a standard dial indicator, providing a clear visual measurement of any deviations from true rotation.

- Versatile Application: The fixture design can be adapted for a wide range of engine and flywheel sizes, making it a universal tool for various automotive and industrial applications.

- Preventative Maintenance: This equipment is invaluable for proactive maintenance and quality checks, helping to identify and correct issues before they cause significant damage.