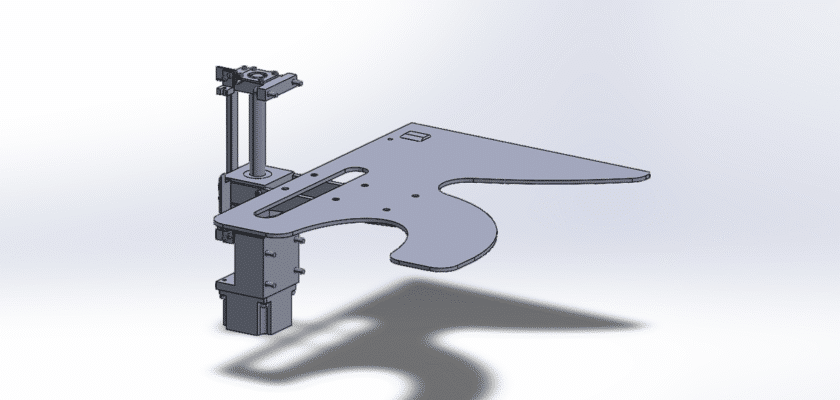

Unlock the secrets of precise linear motion with our Stepper Drive Lift Mechanism drawing. This free, downloadable resource is an essential tool for engineers, hobbyists, and students working on projects that demand exact and repeatable vertical movement, such as 3D printers, automated dispensing systems, or laboratory equipment. The drawing provides a comprehensive view of how a stepper motor is integrated with a lead screw or other mechanical components to create a highly accurate lifting system. It details the interaction between the motor’s rotational output and the linear movement of the lift platform. Unlike other motor types, stepper motors move in discrete “steps,” allowing for open-loop control—meaning no feedback sensor is needed to know the exact position of the lift. This simplicity, combined with high torque at low speeds, makes it an ideal choice for a wide array of applications. Our diagram is perfect for educational purposes, for use as a reference during design and prototyping, or to enhance your knowledge of modern motion control systems.

Principais recursos:

- High-Precision Positioning: The system’s design ensures a precise and repeatable vertical position, which is critical for applications like 3D printing and CNC machines.

- Open-Loop Control: The inherent step-by-step nature of a stepper motor allows the system to operate without a feedback loop, simplifying the overall design and reducing costs.

- Lead Screw Integration: The drawing illustrates the crucial connection between the stepper motor’s shaft and a lead screw, which translates rotational motion into smooth, linear travel.

- High Holding Torque: Stepper motors maintain full torque when stationary, which is vital for preventing the lift from dropping under the weight of its load when the power is on.

- Aplicação versátil: The mechanism’s design is highly adaptable and can be scaled for various loads and travel distances, making it suitable for both small hobbyist projects and larger industrial automation.