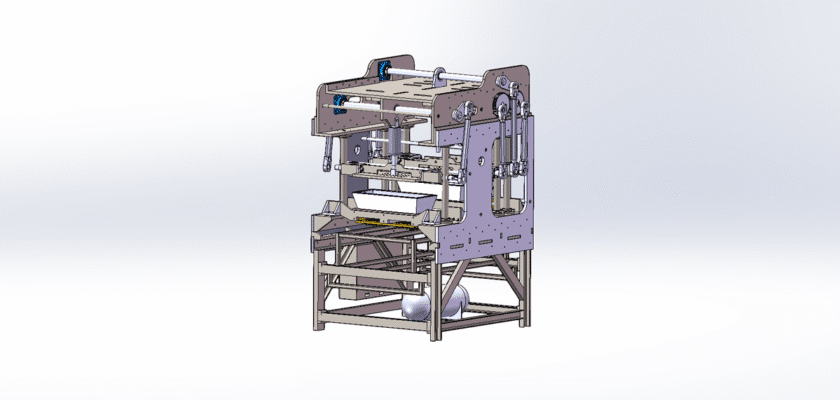

O jelly food filling machine is a specialized piece of equipment designed to accurately and efficiently fill containers with various types of jelly, gelatin, and other viscous food products. This vital component of any food production line automates the filling process, minimizing waste and ensuring product consistency. Our comprehensive engineering drawings of this machine are available for free download, offering an invaluable resource for students, engineers, and manufacturers in the food and beverage industry. These detailed plans provide a deep dive into the mechanical and operational principles that govern these precise machines.

The drawings cover everything from the main frame and hopper to the intricate pumping and nozzle systems. They are designed for compatibility with standard CAD software, making them an ideal starting point for designing your own equipment, or as a reference tool for maintenance and educational purposes. By understanding the inner workings of this machinery, you can improve production efficiency, reduce manual labor, and enhance the overall quality of your jelly products. Download our professional-grade drawings and take the first step towards mastering the art of automated food processing.

Principais recursos:

- Piston and Pump Mechanism: The blueprints detail the precise piston and pump systems that accurately measure and dispense the viscous jelly into containers, preventing over or under-filling.

- Hopper and Agitator Design: Explore the design of the heated hopper and agitator, which maintain the jelly’s liquid state and prevent it from solidifying during the filling process.

- Nozzle and Anti-Drip Technology: The drawings highlight the specialized nozzle designs and shut-off valves that ensure a clean fill with no drips or spills, keeping the production line sanitary.

- Conveyor and Container Handling: Learn about the synchronized conveyor systems and container positioning mechanisms that ensure each cup or sachet is perfectly aligned for filling and sealing.

- Integration with Sealing and Packaging: The plans show how the filling machine is designed to seamlessly integrate with downstream equipment, like heat sealers or capping machines, for a complete production line.