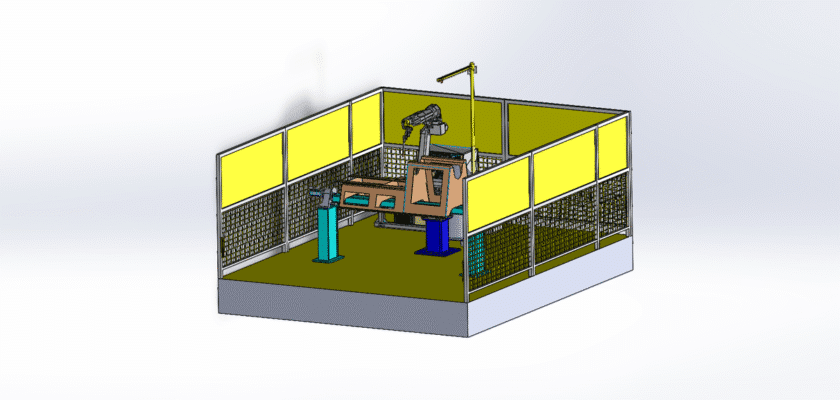

UM robot welding workstation is a highly efficient and precise solution for fabricating the robust frames of prospecting and mining machinery. These machines are engineered to handle the heavy-duty, complex welding required for equipment that operates in demanding environments. Automating the welding process with a robot ensures consistent, high-quality welds, which are crucial for the structural integrity and durability of machinery frames. This free drawing download provides an in-depth look at a typical robotic welding cell, detailing its key components and operational layout. It’s an indispensable resource for mechanical engineers, automation specialists, and students in industrial design who want to understand the design principles of these advanced systems. By using this drawing, you can gain insights into how to improve production efficiency, reduce labor costs, and enhance the safety and quality of welded products. The detailed schematics are designed to provide a clear understanding of the robot’s kinematics, the positioner’s function, and the overall integration of the system.

Principais recursos:

- High Precision & Repeatability: The drawings show a system capable of achieving millimeter-level accuracy, ensuring every weld joint is uniform and meets stringent quality standards. This is vital for safety-critical components like prospecting machinery frames.

- Integrated Positioning System: The design includes a multi-axis positioner that automatically rotates the heavy workpiece, allowing the robot to access all weld seams without manual intervention. This feature significantly boosts productivity and worker safety.

- Durable & Robust Design: The plans detail a workstation built with a heavy-duty frame and a sealed welding environment, engineered to withstand the harsh conditions and heavy loads typical of manufacturing mining equipment.

- Modular e escalável: The drawing highlights a modular design that can be easily configured to accommodate various frame sizes and types. This flexibility allows for quick changeovers and makes the workstation adaptable to different production requirements.