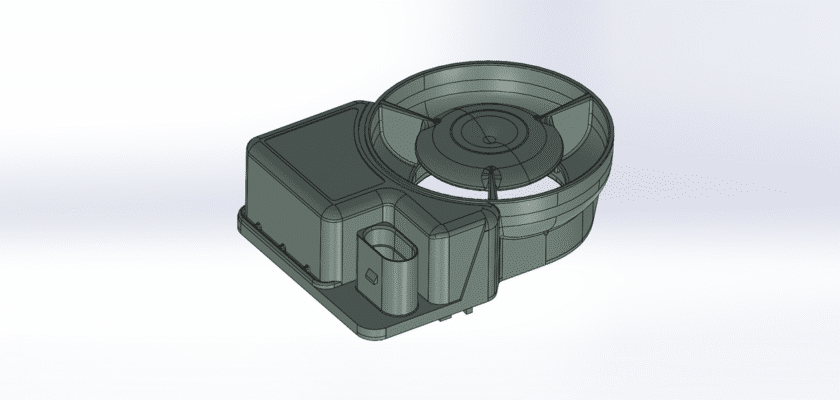

UM robotic assembly workstation is an advanced manufacturing system designed to automate the process of assembling components with high precision and speed. These workstations are at the forefront of the industry, capable of performing complex tasks such as fastening, joining, and inspecting with unparalleled consistency. By replacing manual labor with tireless and accurate robots, companies can significantly increase production output, reduce defects, and improve overall product quality. This comprehensive drawing provides a detailed blueprint of a functional robotic assembly cell, including the robotic arm, end-effector, and peripheral systems. It’s a must-have resource for engineers, students, and manufacturers seeking to understand the mechanics and design of automated assembly lines. The plans highlight a system that is not only efficient but also adaptable, allowing for quick changeovers to accommodate different products and tasks.

Principais recursos:

- High Precision & Repeatability: The drawings demonstrate a system engineered for micron-level accuracy, ensuring every assembled product is identical and meets the highest quality standards.

- Integrated Vision System: The design includes a sophisticated vision system that allows the robot to “see” and identify parts, ensuring correct placement and orientation, even if components are slightly misplaced.

- Flexible End-of-Arm Tooling (EOAT): The plans showcase a modular EOAT design, allowing for quick tool changes so the robot can perform multiple functions, from gripping and placing to screwing and dispensing.

- Robust & Compact Design: The workstation is designed for maximum efficiency in a minimal footprint, making it ideal for integration into existing production lines without requiring extensive floor space.