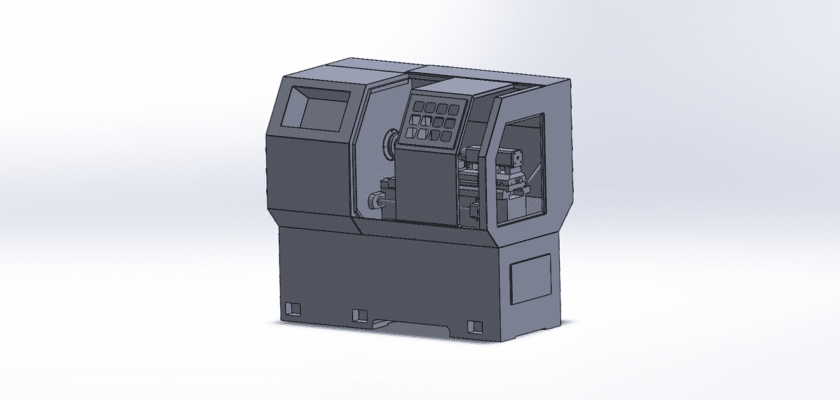

UM small CNC lathe is a computer-controlled machine tool used for shaping materials like metal, plastic, and wood by rotating the workpiece against a cutting tool. Unlike traditional manual lathes, these compact, automated machines offer exceptional precision, repeatability, and efficiency, making them ideal for prototyping, hobbyist projects, and small-batch production. Their small footprint and lower cost make them accessible to home workshops and educational institutions, providing a powerful entry point into modern manufacturing. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade small CNC lathe. This invaluable resource is perfect for mechanical engineers, machinists, and students who want to understand the intricate interplay of mechanical, electronic, and software components that power a CNC machine. The plans illustrate the essential features, from the stepper motor-driven axes to the robust spindle and tool post, giving you the knowledge to build your own machine or simply gain a deeper understanding of CNC technology.

Principais recursos:

- Controle de precisão: The drawing details the use of stepper or servo motors to control the X and Z axes with high accuracy, enabling the machine to create complex shapes and precise dimensions.

- Compact & Robust Design: The blueprints showcase a small, space-saving footprint without compromising on structural rigidity, which is crucial for minimizing vibrations and ensuring a high-quality finish.

- Integrated Spindle System: The design includes a detailed look at the motor-driven spindle, which holds and rotates the workpiece at variable speeds for optimal cutting of different materials.

- Quick-Change Tool Post: The drawing highlights a simple yet effective tool post mechanism that allows for rapid changing of cutting tools, enhancing the machine’s versatility and reducing setup time.