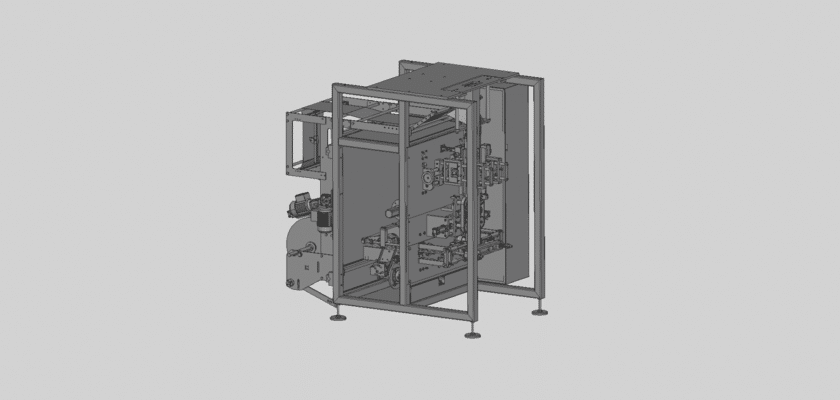

Looking to supercharge your manufacturing line or gain a deeper understanding of modern industrial machinery? Our free, high-quality drawing of a Vertical Packaging Machine is the perfect resource for you. Also known as a Vertical Form Fill Seal (VFFS) machine, this powerhouse is a cornerstone of automated packaging in countless industries. It efficiently forms bags, fills them with product, and seals them, all in a seamless vertical process. This innovative design not only maximizes floor space but also harnesses gravity for a fast, accurate, and incredibly reliable packaging operation.

This comprehensive drawing is an invaluable tool for engineers, students, and manufacturers. It provides a detailed look at the inner workings, component layout, and assembly principles of a VFFS machine. Whether you’re designing a new system, troubleshooting an existing one, or simply looking to expand your technical knowledge, this resource offers a transparent view of the mechanics and automation involved. The drawings are compatible with most major CAD software, allowing for easy integration into your projects. Download this essential drawing today and take the first step towards unlocking greater efficiency and innovation in your packaging processes.

Principais recursos:

- Space-Saving Vertical Orientation: The machine’s upright design is a major advantage, allowing for a smaller footprint on the production floor compared to horizontal systems, which is crucial for optimizing facility layouts.

- High-Speed Automated Operation: This machine automates the entire packaging sequence—from forming the bag from a roll of film to filling and sealing it—enabling high-speed production and significantly boosting output.

- Adaptable Product Handling: The Vertical Packaging Machine is highly versatile, capable of handling a wide range of products including powders, granules, liquids, and solid items, making it suitable for diverse industries like food and pharmaceuticals.

- Precisão e consistência: Automated fillers, often multi-head weighers, work in sync with the machine to ensure each bag is filled with an exact, consistent amount of product, reducing waste and maintaining product quality standards.