Step into the future of manufacturing with our detailed Automated Assembly Line drawing, a conceptual blueprint for building an integrated production system. Available now for a free download, this CAD file is an essential resource for automation engineers, students, and factory planners. Unlike a single machine, this drawing provides a holistic view of a modular system, showcasing how multiple workstations, conveyors, and robotic elements work in harmony to streamline production.

This design serves as a powerful educational tool for understanding process flow, material handling, and systems integration. It illustrates a complete production cycle, from part introduction to final assembly and inspection. By studying this layout, you can grasp the core principles of designing efficient, scalable, and robust automated solutions. Whether you’re planning a small-scale production cell for a workshop or studying for an engineering degree, this drawing offers invaluable insights. Download the file today to start designing smarter manufacturing systems.

Principais recursos:

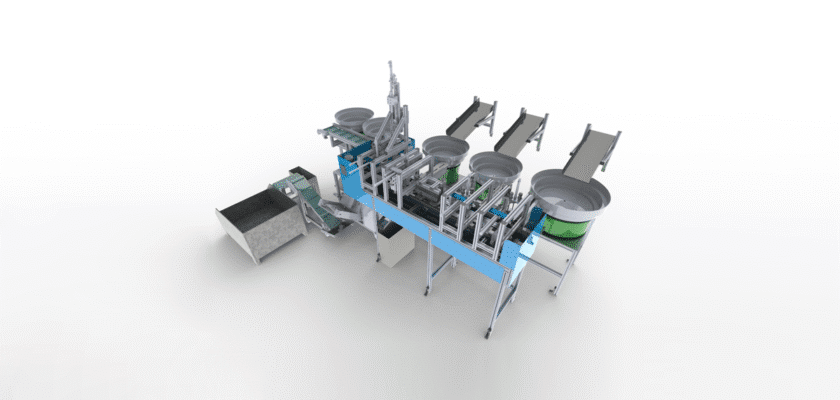

- Modular Workstation Concept: The design features several distinct, standardized workstations (e.g., for part feeding, pressing, inspection) that can be rearranged or customized for different production tasks. [Image showing an overview of the entire line layout from the CAD file]

- Integrated Conveyor System: A central pallet or belt conveyor system is detailed, showing the mechanism for transporting a workpiece seamlessly from one station to the next.

- Robotics and Actuator Integration: The layout includes designated mounting points and operational envelopes for common automation hardware like SCARA robots, pneumatic pick-and-place units, and sensors.

- Complete Process Flow: The drawing provides a top-down view of an entire assembly process, making it an excellent reference for optimizing workflow, identifying potential bottlenecks, and planning factory layouts.