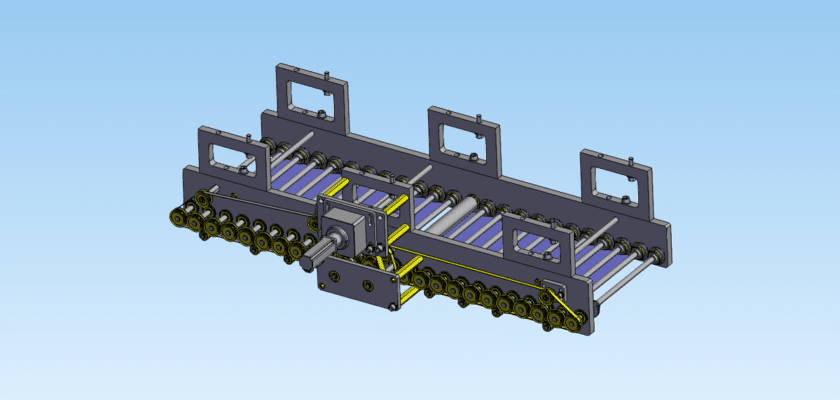

Ensure the safe and efficient transport of delicate substrates with our professional Glass Circuit Board Conveyor drawing. Handling glass-based PCBs requires a departure from standard belt conveyor designs; because glass is prone to scratching and catastrophic shattering, the contact surfaces and vibration dampening of the transport system must be meticulously engineered. This technical blueprint provides a complete design for a specialized roller or edge-drive conveyor system specifically optimized for the unique physical properties of glass and ceramic substrates.

The design focuses on “Minimal Contact” transport logic. By downloading this drawing from MechStream, you receive a detailed assembly that utilizes anti-static, non-marring rollers or high-friction edge belts that grip only the non-functional margins of the board. This prevents any contact with sensitive circuitry or optical coatings on the board’s surface. The mechanism is engineered for smooth acceleration and deceleration profiles to eliminate the “micro-shocks” that can lead to stress fractures in thin glass.

Implementing this professional-grade conveyor solution is essential for cleanroom environments. The documentation highlights the use of low-particle-generation components and includes integrated mounting points for ionization bars to eliminate static charges that attract dust to the glass surface. Whether you are building a line for liquid crystal displays (LCDs), solar panels, or transparent medical electronics, this drawing provides the mechanical precision and structural integrity required to move high-value glass components with zero defects.

Principais recursos:

- Non-Marring Edge Drive: Features specialized belt or roller profiles that support the glass only by its edges, protecting the active circuit area.

- ESD-Safe Roller Material: Specifications for conductive polymers that dissipate static electricity while providing a soft, cushioned interface for the glass.

- Vibration-Isolated Drive System: Engineered with dampened motor mounts and precision-aligned shafts to ensure a laminar, jitter-free transport motion.

- Adjustable Width Framework: Includes a high-accuracy width adjustment mechanism to accommodate various glass panel sizes with sub-millimeter repeatability.

- Integrated Sensor Brackets: Pre-designed mounting slots for high-sensitivity photoelectric sensors that detect transparent materials without false triggers.