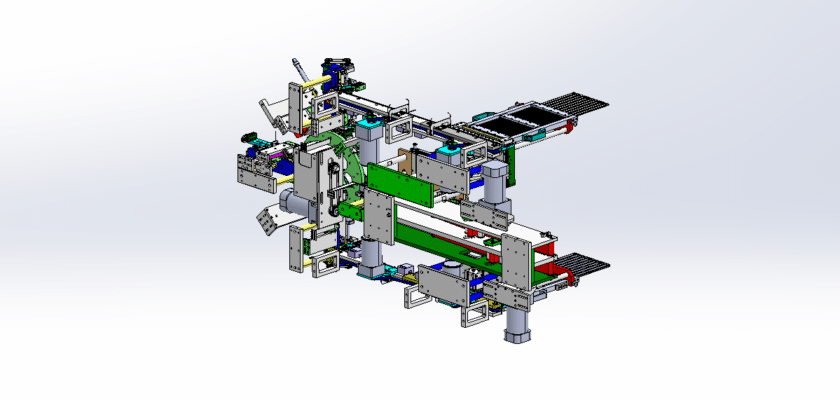

This drawing illustrates a complete USB assembly production line, designed for efficient and automated manufacturing of USB connectors. The layout features multiple workstations optimized for a streamlined assembly process.

Componentes principais:

- Infeed Conveyor:

- Transports raw materials to the initial assembly station.

- Equipped with sensors to detect and control material flow.

- Automatic Insertion Station:

- Mechanically inserts components into the USB housing.

- Features precision alignment tools to ensure accurate placement.

- Soldering Station:

- Utilizes automated soldering machines for secure electrical connections.

- Includes temperature control to prevent damage to sensitive components.

- Testing Station:

- Implements electrical testing to verify functionality of assembled USB connectors.

- Uses automated testing equipment for efficiency and accuracy.

- Outfeed Conveyor:

- Moves finished products to packaging or storage areas.

- Integrated with sorting mechanisms to categorize products based on specifications.

Specifications:

- Production Capacity: Designed for high throughput with minimal downtime.

- Control System: Centralized PLC (Programmable Logic Controller) for real-time monitoring and adjustments.

- Recursos de segurança: Emergency stop buttons, safety guards, and emergency shutdown protocols.

Aplicações:

Ideal for manufacturers in the electronics industry focusing on USB connector production, ensuring high-quality output and reduced labor costs.