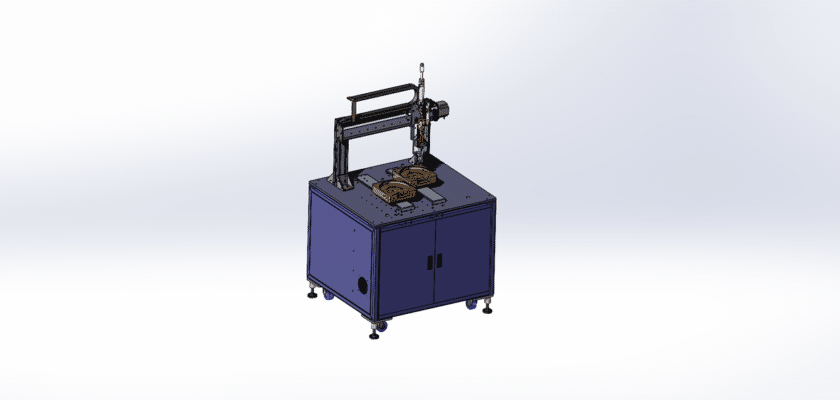

The Air-Blowing Three-Axis Screw Machine is a cutting-edge automation solution designed for precise screw assembly in various manufacturing environments. This machine employs air-blowing technology to facilitate the rapid handling and placement of screws, ensuring high efficiency and accuracy in production processes.

Principais características

- Controle de movimento de três eixos: Offers flexible movement across three axes (X, Y, and Z), allowing for precise positioning and alignment of screws in complex assembly tasks.

- Air-Blowing Technology: Uses a targeted air-blowing mechanism to securely position and guide screws into place, minimizing the risk of misalignment and enhancing productivity.

- Operação de alta velocidade: Capable of fast cycle times, significantly increasing output without compromising on quality.

- User-Centric Design: Features an easy-to-use interface with programmable settings for various screw types and sizes, streamlining the setup process.

- Compact and Lightweight: Designed to occupy minimal floor space while being easily transportable within the production area.

Aplicações

- Montagem Eletrônica: Ideal for fastening components in electronic devices, where precision and speed are paramount.

- Fabricação de automóveis: Suitable for various applications in automotive assembly lines, enhancing assembly speed and accuracy.

- Fabricação Geral: Versatile enough for use in a wide range of industries requiring efficient fastening solutions.

Especificações técnicas

- Fonte de energia: [Especifique os requisitos de tensão e energia]

- Air Pressure Requirement: [Specify air pressure range]

- Dimensões: [Forneça as dimensões da máquina]

- Peso: [Especifique o peso]

Conclusão

The Air-Blowing Three-Axis Screw Machine is an innovative tool that revolutionizes the screw assembly process. Its combination of advanced air-blowing technology and three-axis motion control makes it an indispensable asset for modern manufacturing, ensuring quick, precise, and efficient operations.