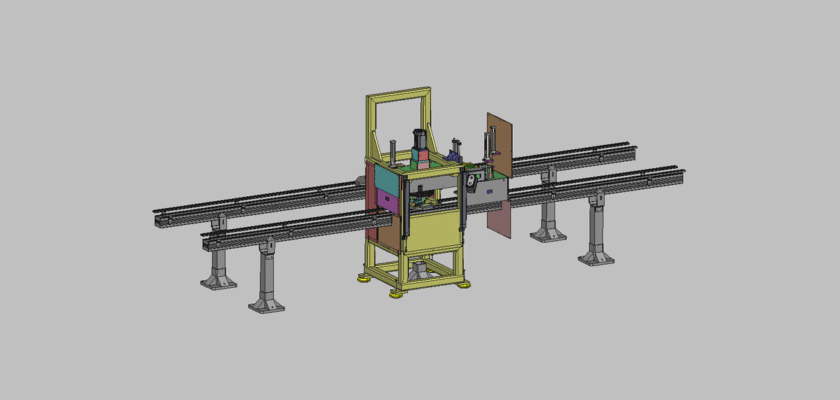

Ensure the highest quality and safety for your battery production with our free drawing of an Automated Electrode Inspection machine. This essential piece of equipment uses advanced vision systems and precision handling to detect even the smallest defects on electrode sheets, a critical step in manufacturing reliable and high-performance lithium-ion batteries. From microscopic pinholes to coating inconsistencies and burrs, this machine performs a rapid, non-contact inspection, eliminating the risk of human error and significantly boosting manufacturing throughput.

This comprehensive drawing is an indispensable tool for engineers, students, and professionals in the fields of battery technology, automation, and machine vision. It provides a detailed look at the mechanical, optical, and control systems that work in concert to achieve flawless quality control. The blueprint is designed to be compatible with standard CAD software, making it perfect for studying the principles of inline quality assurance or as a foundation for your own custom designs. Download this valuable resource today to enhance your understanding and capabilities in the world of advanced battery manufacturing.

Principais recursos:

- High-Resolution Vision System: The drawing details the integration of high-speed line-scan cameras and specialized lighting to capture every detail of the electrode surface.

- Precision Material Handling: It illustrates the servo-driven rollers and tensioning systems that ensure the electrode sheet is transported smoothly and accurately at high speeds without damage.

- Defect Detection & Classification: The blueprint highlights the software-controlled processing unit that analyzes image data in real-time to identify and classify various defects, such as scratches, agglomerates, and coating voids.

- Automatic Rework/Rejection: The drawing shows how the system is designed to either mark defective areas for later rework or automatically reject flawed material from the production line, maintaining quality standards.

- Data Integration: Includes schematics for integrating the inspection system with a central control network, allowing for real-time monitoring and data analysis to optimize the entire manufacturing process.