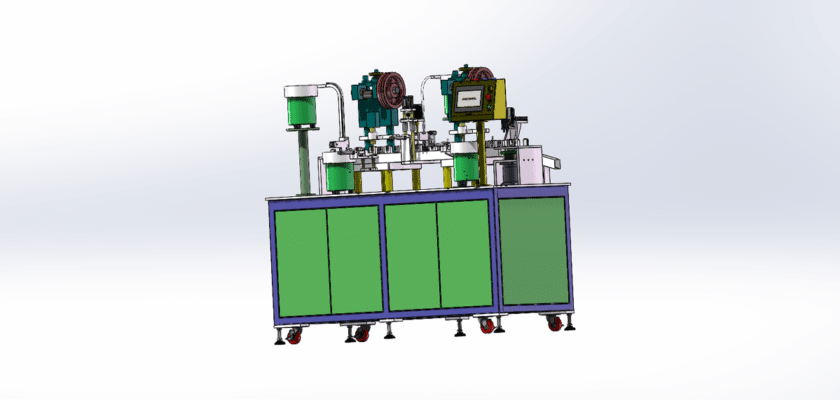

This detailed drawing of an Automatic Assembly Machine illustrates a sophisticated system engineered to enhance the efficiency and precision of component assembly across various manufacturing sectors. Ideal for industries such as automotive, electronics, and consumer goods, this machine optimizes workflows while ensuring consistent quality.

Principais características do desenho:

- Operações totalmente automatizadas: The assembly machine utilizes advanced automation technology to minimize manual intervention, significantly increasing throughput and operational efficiency throughout the production process.

- Design modular: The equipment features a modular architecture, allowing for easy scalability and customization to accommodate different products and production volumes.

- Sistemas de manuseio de precisão: Equipped with high-precision robotic arms and conveyors, the system ensures accurate placement and alignment of components, critical for achieving optimal assembly quality.

- Interface de controle amigável: O painel de controle intuitivo permite que os operadores programem e monitorem facilmente o processo de montagem, facilitando ajustes rápidos para diferentes necessidades de fabricação.

- Controle Integrado de Qualidade: Sistemas de monitoramento e inspeção em tempo real são incorporados para garantir que cada conjunto atenda a rigorosos padrões de qualidade, reduzindo defeitos e aumentando a confiabilidade.

- Construção robusta e durável:Construída com materiais de alta qualidade, a máquina foi projetada para longevidade e confiabilidade, garantindo desempenho ideal em ambientes industriais exigentes.

This drawing serves as an essential reference for engineers and manufacturers looking to implement effective and efficient assembly solutions in their production processes.