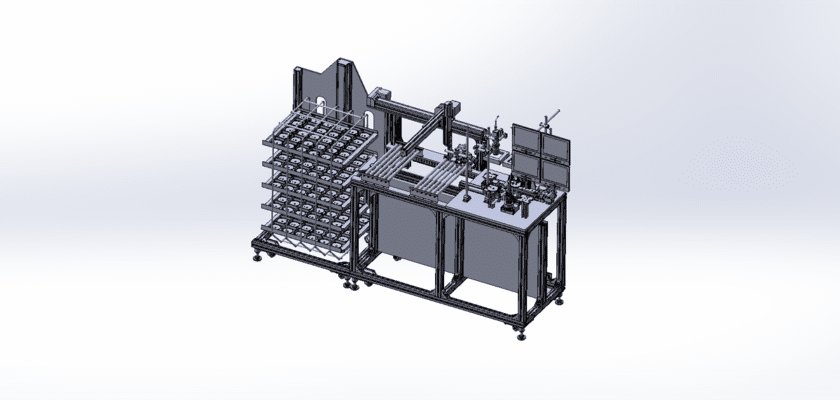

This drawing illustrates an Automatic Assembly Visual Detection Equipment designed for real-time quality control in manufacturing environments. The system utilizes advanced imaging technology to detect assembly errors, ensuring high standards of product integrity.

Key Components

- Camera System:

- High-resolution cameras positioned strategically to capture detailed images of the assembly line.

- Capable of both 2D and 3D imaging for comprehensive analysis.

- Lighting Setup:

- Integrated LED lighting to enhance image clarity and reduce shadows.

- Adjustable lighting angles to accommodate different assembly configurations.

- Processing Unit:

- Centralized processing unit equipped with machine learning algorithms for image analysis.

- Real-time data processing capabilities to provide immediate feedback.

- User Interface:

- Touchscreen interface for operator interaction.

- Visual display of detected anomalies and suggested corrective actions.

- Conveyor System:

- Automated conveyor belt for seamless integration into existing assembly lines.

- Speed synchronization with detection equipment to ensure accurate timing.

- Alarm System:

- Visual and auditory alarms to alert operators of detected issues.

- Integration with factory management systems for comprehensive reporting.

Functionalities

- Error Detection:

- Identifies misalignment, missing components, and incorrect assembly.

- Data Logging:

- Records detection events for quality assurance and compliance tracking.

- Adjustable Parameters:

- Customizable settings for different products and assembly processes.

Applications

- Ideal for electronic, automotive, and consumer goods manufacturing industries.

- Enhances efficiency and reduces waste by ensuring only correctly assembled products proceed to the next stage.