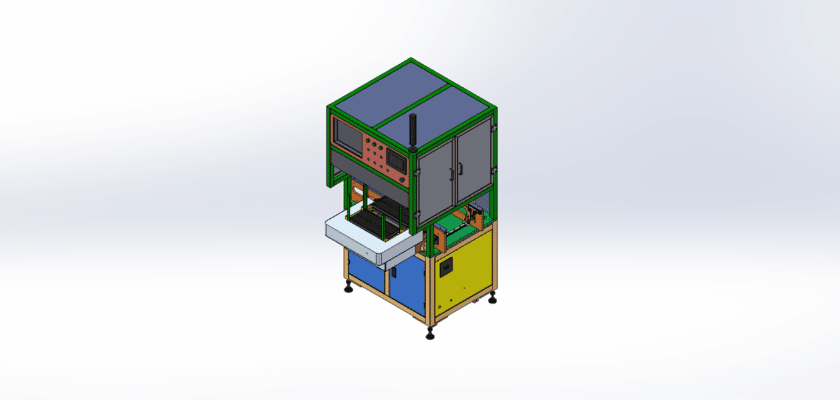

O Automatic DIMM Insertion Machine Drawing provides a detailed reference for an advanced industrial machine designed specifically for inserting DIMM (Dual In-line Memory Module) components onto circuit boards with precision and efficiency. This equipment is widely used in electronics manufacturing, ensuring consistent quality and increased productivity in high-volume production lines.

Um dos seus principais características é seu mecanismo de inserção automatizado, which accurately aligns and places DIMM modules onto circuit boards without manual intervention. This automation significantly reduces error rates and improves overall assembly quality.

Outra característica de destaque é a sua sistema de alinhamento de alta precisão, ensuring the proper positioning of DIMM connectors during insertion. This eliminates the risk of misalignment, damage, or faulty connections.

O interface de controle inteligente provides user-friendly programming and real-time monitoring of the insertion process. Operators can easily adjust parameters, track production progress, and ensure consistent quality across batches.

Além disso, o operação de alta velocidade of the machine allows for rapid insertion cycles, optimizing throughput while maintaining precision in every step of the process.

Isso é construção robusta ensures long-lasting durability and reliable performance in demanding manufacturing environments. Maintenance requirements are minimal, keeping downtime low and efficiency high.

Em conclusão, o Automatic DIMM Insertion Machine is an essential solution for electronics manufacturers seeking precision, efficiency, and reliability in DIMM module assembly. Its advanced automation, intelligent controls, and durable design make it an indispensable tool for modern production lines.