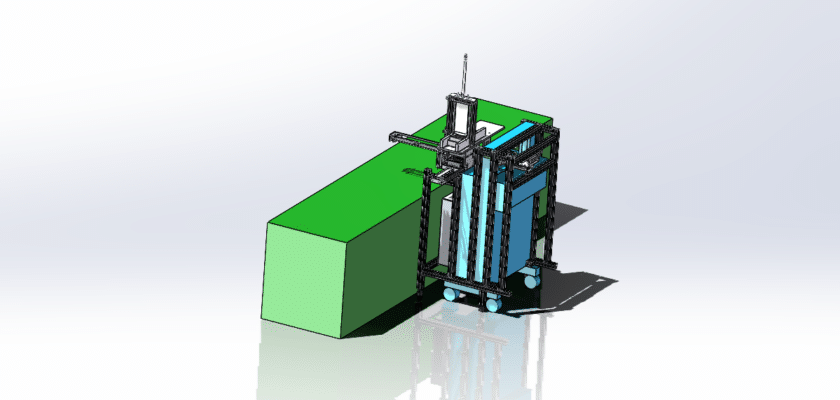

An Automatic Folding and Bundling Machine for Gloves Drawing is a technical illustration that outlines the components and layout of a machine designed for the efficient folding and bundling of gloves, typically used in manufacturing or packaging environments. This machine enhances productivity and ensures consistent packaging standards.

Principais recursos:

- Feeding System: Diagrams showing the mechanism that automatically feeds gloves into the machine, ensuring a continuous supply for processing.

- Folding Mechanism: Representation of the components responsible for folding the gloves, detailing the folding arms or plates that ensure precise and uniform folding.

- Bundling Station: Information about the section where folded gloves are grouped and bundled together, including any mechanisms for tying, wrapping, or sealing the bundles.

- Control Panel: Illustrations of the control unit that manages the entire operation of the machine, allowing operators to monitor processes, adjust settings, and manage production rates.

- Conveyor System: Details about the conveyors that transport gloves through various stages of folding and bundling, ensuring smooth and efficient movement.

- User Interface: Information about the touchscreen or control panel that provides operators with access to machine settings, monitoring capabilities, and production data.

- Data Output Systems: Diagrams showing how production data, including counts and bundle quality, are logged and communicated, with digital displays for immediate feedback.

- Mechanical Framework: Information about the structural components that support the machine, ensuring stability and precision during operation.

- Power Supply: Details regarding the electrical requirements and backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of automatic folding and bundling machines for gloves, ensuring high standards of efficiency, quality control, and operational effectiveness in packaging processes.