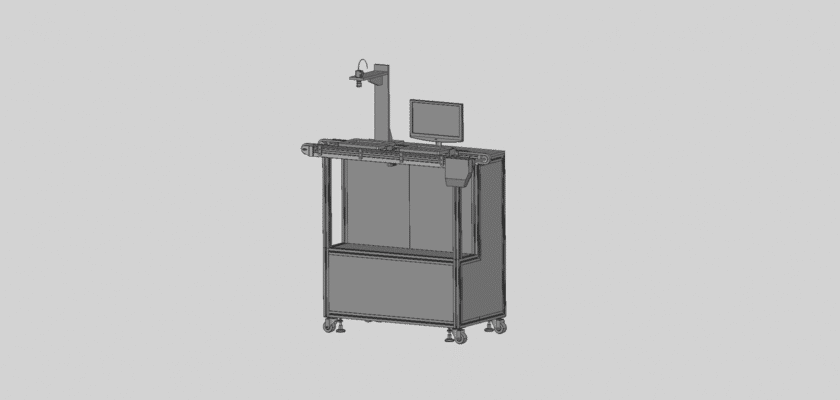

Eleve seu processo de fabricação com nosso desenho detalhado de um Equipamento de Inspeção Automática para a Aparência de Produtos Moldados por Injeção. Este arquivo CAD abrangente está disponível para download gratuito, fornecendo um recurso inestimável para engenheiros, designers e estudantes que buscam compreender e implementar soluções avançadas de controle de qualidade. No mercado competitivo atual, garantir o acabamento impecável de peças moldadas por injeção é fundamental para a reputação da marca e o desempenho do produto. Este equipamento foi projetado para automatizar a detecção de defeitos superficiais, como arranhões, marcas de afundamento, rebarbas e variações de cor, melhorando significativamente a eficiência e a precisão em relação à inspeção manual.

Ao baixar este desenho, você terá acesso a um projeto bem estruturado que integra sistemas de visão computacional, robótica e manuseio de materiais. Ele serve como uma excelente referência para o desenvolvimento de suas próprias estações automatizadas de controle de qualidade ou para fins educacionais, para o estudo da mecânica e eletrônica envolvidas. Entenda a complexa montagem de câmeras, iluminação e mecanismos de triagem que trabalham em harmonia para identificar e segregar produtos defeituosos em tempo real. Este projeto prioriza confiabilidade e precisão, tornando-se um pilar fundamental para qualquer instalação moderna de moldagem por injeção que busque uma produção com zero defeitos.

Principais recursos:

- Sistema de visão de alta velocidade: Incorpora câmeras industriais e iluminação especializada para capturar imagens de alta resolução para detecção precisa de defeitos em diversas superfícies de produtos.

- Mecanismo de classificação automatizado: Possui um braço robótico ou sistema pneumático para separar automaticamente peças defeituosas da linha de produção, garantindo que somente produtos de qualidade sejam produzidos.

- Design modular e compacto: O desenho mostra um layout com eficiência de espaço, permitindo fácil integração em linhas de produção existentes com interrupção mínima.

- Layout abrangente de componentes: São fornecidas vistas detalhadas de todos os principais componentes, incluindo a correia transportadora, suportes de sensores, painel de controle e estrutura.