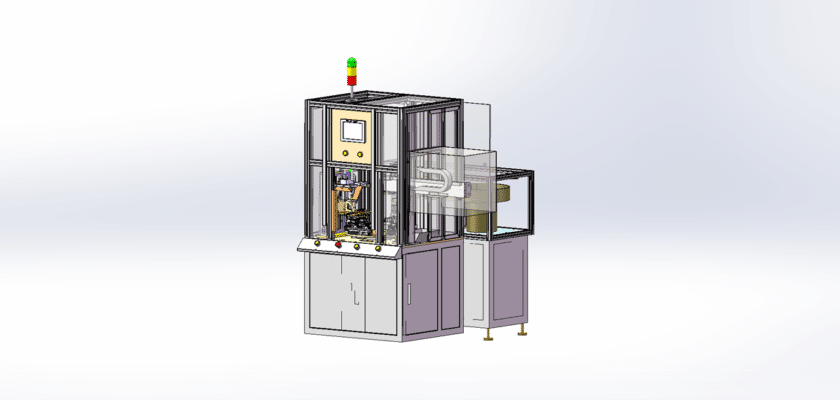

The Automatic Screw Locking Machine is a sophisticated automation solution designed to facilitate the efficient and precise fastening of screws in various manufacturing applications. This machine significantly enhances assembly line productivity by automating the screw locking process, ensuring consistent quality and reducing manual labor.

Key Features

- Operação totalmente automatizada: The machine automates the entire screw locking process, from feeding screws to tightening, which streamlines workflows and minimizes human error.

- Advanced Torque Control: Utilizes precise torque settings to ensure screws are fastened securely without the risk of over-tightening, preserving the integrity of the components.

- Interface amigável ao usuário: Features a digital control panel that allows operators to easily configure settings, monitor real-time performance, and conduct troubleshooting, enhancing operational efficiency.

- Versatile Design: Capable of accommodating various screw sizes and types, making it suitable for a wide range of applications in different industries.

- Compact and Durable Construction: Designed to fit within limited production spaces while being built to withstand the demands of industrial environments, ensuring long-term reliability.

Applications

- Electronics Manufacturing: Ideal for assembling electronic devices that require precise and secure screw fastening.

- Automotive Production: Suitable for various applications in automotive assembly lines, ensuring strong and reliable connections.

- General Manufacturing: Versatile enough for use in numerous industries, including furniture, appliances, and consumer goods.

Technical Specifications

- Power Supply: [Specify voltage and power requirements]

- Locking Mechanism Type: [Specify type, e.g., electric, pneumatic]

- Dimensions: [Provide dimensions of the machine]

- Weight: [Specify weight]

Conclusion

The Automatic Screw Locking Machine is an essential tool for manufacturers seeking to enhance assembly line efficiency and ensure high-quality screw fastening. Its combination of advanced automation, precise torque control, and user-friendly operation makes it a valuable asset in modern manufacturing environments, driving productivity and quality in assembly processes.