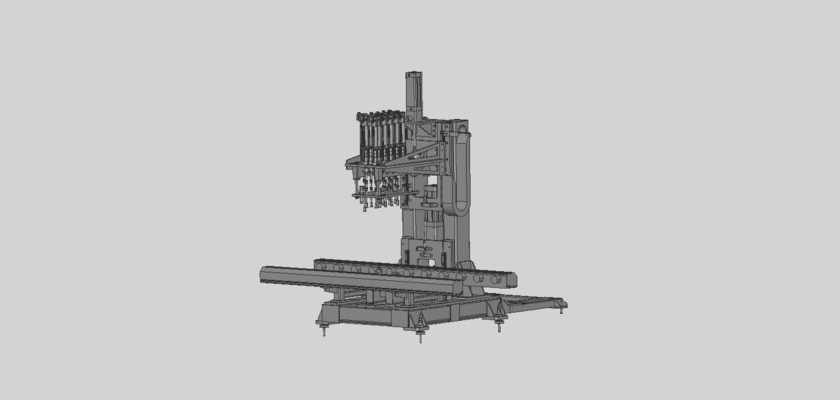

The Automatic Screw Tightening Machine is designed to enhance assembly line efficiency by automating the screw fastening process. This machine minimizes manual labor, reduces errors, and increases production speed.

Key Features

- Automated Operation: The machine features a programmable logic controller (PLC) that allows for precise control of the tightening process.

- Adjustable Torque Settings: Users can set different torque levels based on the specifications of the screws and materials being used.

- Versatile Design: Capable of handling various screw sizes and types, making it suitable for diverse applications.

- Safety Mechanisms: Equipped with emergency stop buttons and safety guards to protect operators during operation.

- Interface amigável ao usuário: A touchscreen panel provides easy access to settings, monitoring, and maintenance alerts.

Components

- Feeding Mechanism: Automatically feeds screws into the tightening head, ensuring a continuous supply.

- Tightening Head: The part of the machine that grips and tightens screws; can be customized based on the application.

- Base Frame: A sturdy structure that supports all components and minimizes vibration during operation.

- Control Panel: Houses the PLC and user interface, allowing for real-time adjustments and monitoring.

Applications

- Manufacturing: Ideal for electronics, automotive, and consumer goods assembly lines.

- Construction: Useful in fastening components in modular construction.

- Maintenance: Can be used in repair shops for efficient assembly and disassembly.

Conclusion

The Automatic Screw Tightening Machine is a vital tool for modern manufacturing, providing speed, accuracy, and reliability while reducing operational costs. Its design and features make it an essential addition to any assembly line focused on efficiency and quality.