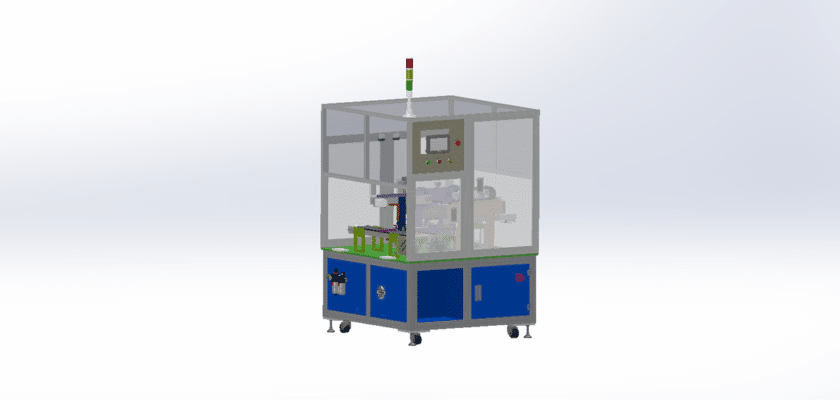

A Battery Core Automatic Inspection Equipment Drawing is a detailed technical illustration that showcases the components and layout of machinery designed for the automated inspection of battery cores.

Principais recursos:

- Estação de Inspeção: Diagrams of the main inspection area where battery cores are positioned for evaluation, including guides or fixtures to ensure proper alignment.

- Sensores e Câmeras: Representation of various sensors (optical, ultrasonic) and cameras used for detecting defects, measuring dimensions, and assessing quality.

- Sistema de transporte: Details of the conveyor belt or automated handling system that transports battery cores through the inspection process.

- Painel de controle: Illustrations of the user interface where operators can monitor the inspection process, adjust settings, and view results.

- Unidade de Processamento de Dados: Diagrams showing the central processing unit that analyzes sensor data, generates reports, and interfaces with other systems.

- Mecanismo de Saída: Information on how the inspected battery cores are categorized, sorted, or rejected based on inspection results, including any automated arms or sorting systems.

- Fonte de energia: Details regarding the power requirements and sources, such as electrical connections or battery backups for uninterrupted operation.

This drawing serves as an essential reference for engineers and technicians involved in the design, assembly, and maintenance of battery core inspection equipment, ensuring efficient quality control and operational reliability.