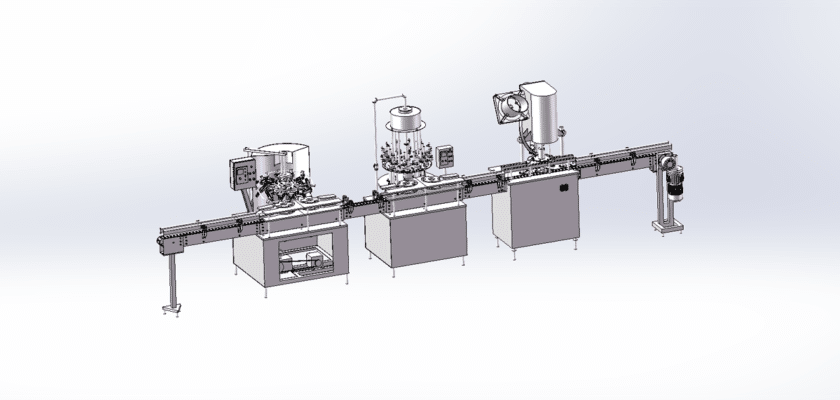

O Fully Automated Bottled Beverage Production Line is a state-of-the-art system designed for high-efficiency beverage production. It integrates filling, capping, labeling, and packaging processes, providing a streamlined solution for industries looking to scale their production capabilities. This production line is engineered to handle various beverage types, including carbonated drinks, juices, and bottled water, ensuring high performance and consistency.

Principais recursos:

- Automação completa: The production line automates all critical steps in the beverage bottling process, from filling to capping and labeling. This reduces labor costs, improves speed, and ensures precision.

- Operação de alta velocidade: Designed for high-volume production, the automated system can efficiently process hundreds or thousands of bottles per hour, meeting the demands of large-scale production.

- Versatility in Beverage Types: Capable of handling a range of beverages, from carbonated drinks to juices and still water, this system offers the flexibility to adapt to different production needs.

- Sistema de Controle Integrado: The advanced control panel allows operators to monitor and adjust all aspects of the production line, ensuring smooth operations and minimizing downtime.

- Reliable and Durable: Built with high-quality materials, the production line is designed to endure demanding production environments, offering long-lasting performance and reliability.

Faça o download do Fully Automated Bottled Beverage Production Line Drawing to explore the detailed schematics and discover how this high-performance system can enhance your production process.