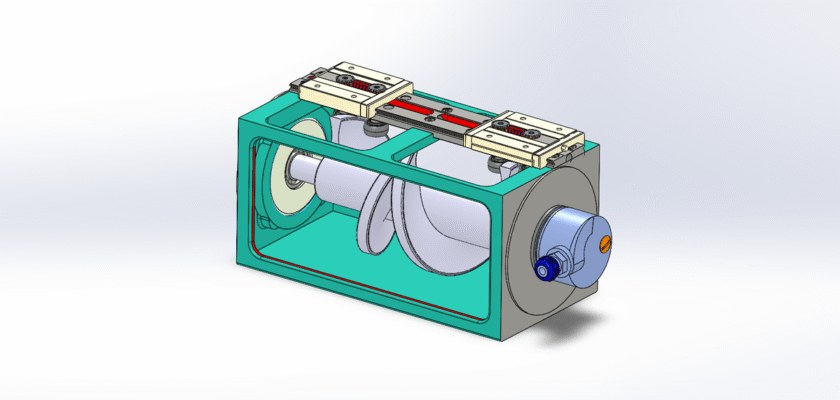

Leve sua usinagem CNC para o próximo nível com este desenho detalhado e gratuito de uma Caixa de Controle Adaptativo CAM. O controle adaptativo é uma tecnologia de ponta que revoluciona as operações CNC, ajustando automaticamente os parâmetros de usinagem em tempo real. Este desenho fornece uma visão detalhada dos componentes internos e circuitos de uma caixa de controle projetada para otimizar o desempenho, proteger ferramentas e melhorar a qualidade das peças.

Ao contrário dos sistemas CNC tradicionais com parâmetros fixos, uma caixa de controle adaptável usa sensores para monitorar condições de corte em tempo real, como força de corte, torque do fuso ou vibração. Em seguida, ele ajusta dinamicamente as taxas de avanço e as velocidades do eixo para manter o desempenho ideal. Este desenho técnico é um recurso inestimável para engenheiros, amadores e estudantes que buscam entender o funcionamento interno desta tecnologia avançada de automação. Baixe-o hoje mesmo para obter uma vantagem competitiva e liberar todo o potencial dos seus processos de usinagem.

Principais recursos:

- Ajuste de parâmetros dinâmicos: O desenho ilustra como os sensores e a lógica de controle do sistema trabalham juntos para ajustar automaticamente as taxas de avanço e as velocidades do eixo, otimizando o processo de corte em tempo real.

- Proteção aprimorada de ferramentas: Ao evitar força ou torque excessivos, a caixa de controle adaptável minimiza o desgaste da ferramenta e reduz o risco de quebra da ferramenta, prolongando a vida útil das suas ferramentas de corte.

- Melhoria da qualidade das peças: A capacidade do sistema de compensar variações na dureza do material ou no desgaste da ferramenta garante uma geometria consistente e precisa da peça, mesmo em condições de usinagem desafiadoras.

- Eficiência de usinagem otimizada: Aprenda como a caixa de controle permite maiores taxas de remoção de material, levando a máquina aos seus limites dentro de restrições operacionais seguras, reduzindo os tempos de ciclo e aumentando a produtividade.

- Layout de circuito e componentes: O desenho inclui um layout detalhado dos componentes eletrônicos, fornecendo informações sobre o circuito de controle e como vários sinais são processados para ajustes em tempo real.