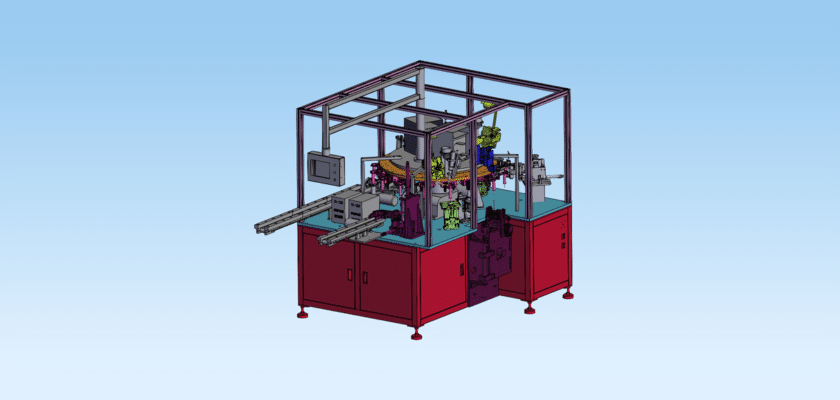

Achieve unmatched quality and consistency in capacitor manufacturing with this vital free drawing download: the complete plans for a Circular Capacitor Through-Core Welding Machine. This highly specialized, automated machine is indispensable for producing high-reliability power capacitors and energy storage units, where the connection between the electrode foil and the terminal is often made through the component’s core. The through-core welding process ensures minimal electrical resistance and maximum mechanical strength, which are essential for high-performance and long-life capacitors used in power electronics, EVs, and industrial inverters. MechStream offers these detailed schematics to empower engineers and manufacturers dedicated to advancing energy component technology.

The machine’s design integrates a precise rotary indexing system to handle the circular components and a highly controlled welding head (often laser or ultrasonic) to perform the weld through the core opening. The documentation provides critical insight into the complex component handling (feeding, indexing, and ejection), the necessary laser or welding source integration, and the precision alignment systems needed to ensure a clean, reliable joint every time. Gaining access to this powerful blueprint is the key to optimizing your production line for these critical components. Download your free Circular Capacitor Through-Core Welding Machine drawing today and solidify your foundation in high-reliability energy storage manufacturing!

Principais recursos:

- High-Precision Indexing: Features a robust rotary table mechanism for accurate and repeatable positioning of the circular capacitor bodies.

- Through-Core Access: Specifically designed tooling and welding optics to successfully perform the weld deep within the core structure.

- Minimal Heat Impact: Engineered to use precise welding methods (e.g., laser or ultrasonic) to minimize thermal stress on the capacitor’s sensitive internal components.

- Manuseio automatizado de componentes: Includes schematics for efficient, automated loading and unloading systems to maximize cycle speed.

- Comprehensive Machine Drawing: O livre desenho package details the mechanical rotary system, welding station integration, and control system architecture.