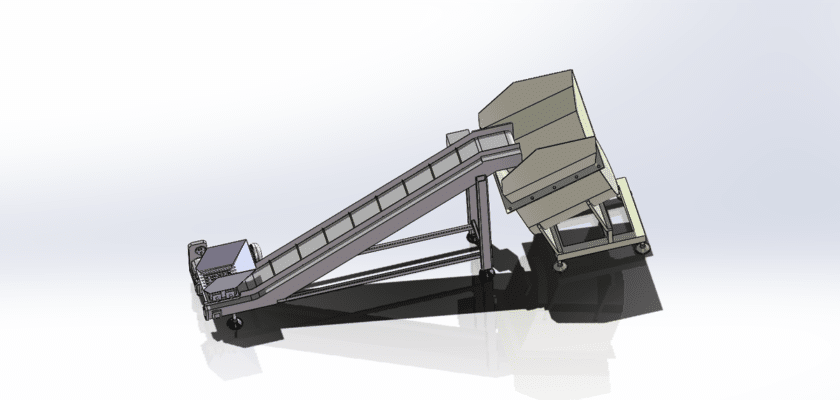

O Chip Conveyor Drawing provides a thorough visual representation of a chip conveyor system specifically designed for the efficient transport of metal chips, shavings, and other by-products generated during machining processes. This drawing highlights the key components, structural features, and operational capabilities essential for effectively handling and disposing of chips in manufacturing environments.

Key Components Illustrated:

- Conveyor Mechanism: The drawing prominently features the conveyor mechanism, which may consist of a belt or chain system designed to move chips smoothly and efficiently. The design is tailored to handle the specific characteristics of metal chips, ensuring reliable transport.

- Frame Structure: Illustrated is the robust frame, typically constructed from high-strength steel or aluminum. This frame provides stability and support to withstand the weight of the chips and the rigors of continuous operation in a manufacturing setting.

- Drive Assembly: The drawing includes details of the drive mechanism, featuring a motor, pulleys, and gear systems that provide the necessary power to move the conveyor. This assembly is crucial for maintaining consistent speed and efficient chip handling.

- Tensioning System: An adjustable tensioning mechanism is depicted, which ensures optimal tension on the conveyor belt or chain. Proper tension is essential to prevent slippage and ensure smooth operation, especially when handling varying loads.

- Chip Hopper and Discharge Chute: The drawing highlights the chip hopper at the intake, which collects chips from machining operations, and the discharge chute that directs the chips to a designated disposal area or container.

- Safety Features: Important safety elements such as emergency stop buttons, safety guards, and accessible maintenance points are emphasized, ensuring a safe working environment for operators and compliance with industry standards.

- Modular Design: The conveyor may feature a modular design, allowing for easy customization and integration into existing production lines, enhancing its adaptability to different operational needs.

Applications:

- Metalworking and Machining: Ideal for transporting metal chips generated during machining processes, ensuring efficient waste management and minimizing downtime.

- Manufacturing: Plays a critical role in various manufacturing settings where metalworking operations occur, helping maintain a clean and organized workspace.

- Recycling: Can be used in recycling applications to transport collected metal scraps for processing or remanufacturing.

Overall Impression

O Chip Conveyor Drawing serves as a vital resource for engineers, designers, and operators involved in the development, implementation, and maintenance of chip conveyor systems. By detailing the essential components and their interrelationships, this drawing aids in ensuring efficient and safe transport of metal chips. Understanding this drawing allows stakeholders to make informed decisions regarding the design and functionality of chip conveyors tailored to their specific applications, ultimately contributing to improved productivity and operational efficiency in manufacturing environments.